With all due respect to Coco Chanel and the little black dress, green is the hottest color in the business world these days. Businesses in every industry are seeking ways to minimize their environmental footprints. Fewer materials used. Less waste generated. More materials recycled. Less energy consumed. More sustainable sourcing. Nearly any input, product or process has the potential to be more earth-friendly in some way.

In an effort to explore this trend, we have created a three-part blog series on the “greening” of marketing communications. This first installment looks at commercial print, a topic of particular interest to those of us at Taylor.

5 ways to make printing more sustainable and less expensive

Commercial print often comes under scrutiny for the sheer volume of natural resources consumed and waste generated. Indeed, every printed piece that you encounter on a daily basis reflects a series of decisions that influence the total environmental footprint of that item:

- The size, shape and design of the piece.

- The substrate selected.

- The printing technology used.

- The quantity printed versus the quantity needed.

- The shipping and storage logistics utilized, and more.

However, thoughtful decision making can dramatically reduce the environmental footprint of a printed piece. Even better, greener alternatives often reduce the total cost of ownership of the items printed. With that win/win proposition in mind, we will examine the five ways you can make printing more earth-friendly and cost-effective.

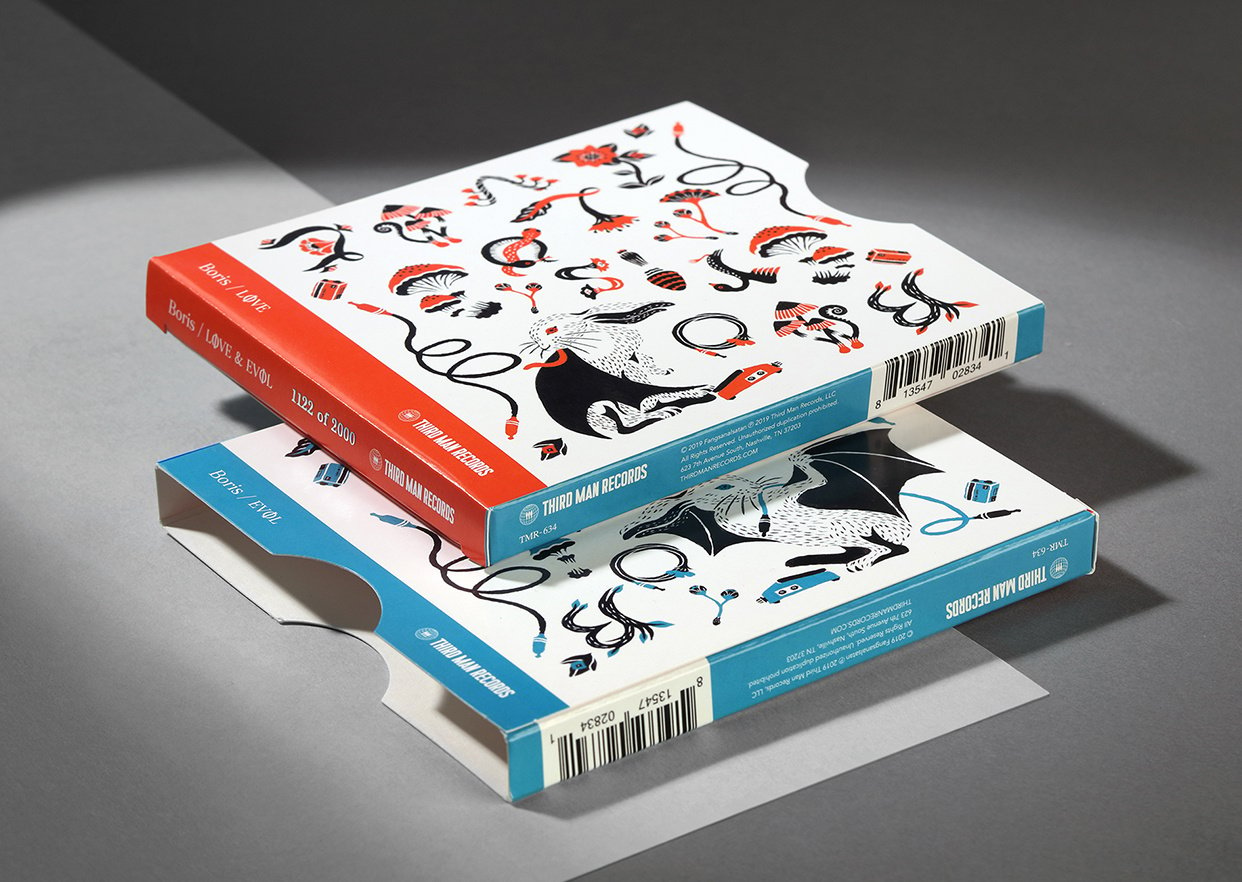

#1: Simple designs minimize the volume of materials used

Environmentally conscious printing starts with simple design. It’s all about the first of the four “R’s” of sustainability: reduce, reuse, recycle, renew. To minimize your environmental footprint, design the printed piece to reduce the volume of raw materials consumed.

Creating a folded carton package for a consumer product? Specify the smallest carton that will “fit” the product. Designing a new print collateral system for Product X? Skip a few photos, thin the prose and cut the page count. Selecting a print substrate? Go with the thinnest, lightest basis weight possible. Considering special embellishments? Try to do without. Every time you add a die cut, you’re creating a die that must be discarded and trimming raw material that will end up as waste. Pay close attention to basic design decisions like these. By doing so, you can dramatically reduce the materials you consume and the money you spend.

For more inspiration, explore the Circular Design Guide created by IDEO and the Ellen MacArthur Foundation. Circular Design is rooted in the belief that we are “an intimately connected web of people, spanning the globe.” Simply put, how we utilize raw materials and energy ultimately affects someone else, somewhere else.

#2: Selective sourcing enables earth-friendly substrates

The substrate you choose to print on is another key decision point. This goes far beyond mere basis weight. How the substrate is sourced directly impacts how sustainable it is.

For example, the Sustainable Forestry Initiative (SFI®) seeks to shape the practices of the forest products industry in North America. Their ultimate goal is to maintain healthy, resilient forests. Likewise, the Forest Stewardship Council (FSC®) (FSC®-C002101) promotes “environmentally sound, socially beneficial and economically prosperous management of the world’s forests.” Want to minimize your impact on the world’s forests? Look for SFI or FSC® certification when you select a paper substrate.

Better yet, consider “tree-free” paper. Bamboo, hemp, wheat straw and sugarcane waste are all being used as substitutes for wood pulp. Each raw material is based on a plant that grows far more quickly than a tree. The pulp-making process for such non-wood sources is also less energy intensive. Looking for a more earth-friendly paper? Conservatree’s Guide to Environmental Paper offers a wealth of information on environmentally sound options.

.jpg?width=698&name=Blog%20Body%20Image%20%E2%80%93%205%20Ways%20(2).jpg)

#3: Sustainable technology reduces environmental impact

One could argue that printing technology is all the same. After all, it’s simply a matter of laying down ink, dye or toner on a substrate material to create an image. That’s where the similarities end, however. Technology plays an outsized role in the sustainability of any printed piece.

Consider printing press technology. Generally speaking, digital printing presses consume more energy than a comparable offset press. However, they also utilize far fewer hazardous chemicals, use less water and do not require the creation of printing plates or blankets. Most would say that digital is more environmentally sound than offset overall. If the size of your print run is on the small side, it will almost certainly be more economical as well.

The technological decisions also extend to other aspects of the printing process. Totally chlorine-free (TCF) paper is made from wood pulp that was not bleached with any carcinogenic, chlorine-based compounds. Soy-based inks replace the petroleum base of traditional printing inks. The latest aqueous and UV coatings produce few VOCs and are easily recyclable. Your next print job might incorporate all of these latest technologies. Then again, it might not. Want to be green? Ask your printer about the press, paper and finishing technologies available to you.

#4: Slashing waste eliminates non-productive uses of materials

Once an item is on press, every item printed represents the consumption of paper, ink and energy. Reducing waste at this stage is of paramount importance to your environmental footprint. Fortunately, there are many things that can be done to minimize wasteful consumption.

For example, start proofing items online instead of on paper. Be open to resizing an item to fit standard sheet sizes. Ask the printer to gang other jobs with yours to maximize the use of paper. Avoid formats that require bleeds and excessive trimming. In yet another win/win, all of these ideas are likely to save you money to boot.

Incidentally, the digital-versus-offset decision is also in play here. Because digital presses require far smaller print overages in the set-up process, they produce less paper waste up front. Printing on demand also provides a better match between the quantity printed and the quantity needed. This reduces obsolescence and ultimately keeps finished items out of the recycling bin. When you consider these waste-reduction advantages, the case for digital gets even stronger.

#5: Smart logistics minimize shipping and storage

The fifth item on the list – smart logistics – considers the things that happen before and after an item is printed. As it turns out, shipping and storage are surprisingly big components of your overall footprint.

Consider the ecological impact of buying print or paper stock from overseas. That material must be shipped to North America on a container ship. Those ships typically burn 5,000 tons of fuel on a single trip across the ocean. In fact, cargo ships are now estimated to generate 3% of the world’s total greenhouse gas emissions. That same pattern continues on dry land. Semi trucks handle the vast majority of shipments domestically. Averaging just 4 to 8 miles per gallon, trucks contribute 6% of the nation’s total greenhouse gases.

Much like the “farm-to-table” movement in restaurants, you can mitigate these issues by sourcing with geography in mind. Buy your print services from a partner who maintains a strategic network of print facilities throughout North America. Ask if they can source paper produced at mills in North America instead of Asia or elsewhere. Use print-on-demand technology to reduce the volume of materials that must be stored in climate-controlled warehouses. By doing these things, you’ll help reduce the staggering tonnage of paper that is warehoused and shipped every single day.

Protecting the environment and quality of life

Taylor is one of the largest graphic communications companies in North America – and one of the most environmentally conscious. Each year, we set aggressive goals pertaining to recycling, diverting waste to energy, minimizing hazardous byproducts and more. This commitment is evident in our corporate value statement on sustainability:

We will protect the environment and the quality of life of our colleagues, customers and community.

Look for the second part of this blog series when we look at continuous variable packaging. “CVP” is an innovative packaging technology that is changing the economics – and ecological impact – of warehousing and fulfillment.