With all of the semi-trucks, delivery vans, airplanes and freight trains in transit each day, one thing is abundantly clear: The U.S. freight and logistics market is enormous. Currently estimated at more than $1.3 trillion with a “t,” our entire economy hinges on the ability to move items from Point A to Point B.

Of course, with all of that shipping and warehousing, there is a massive need for shipping labels. Thermal labels are the pressure-sensitive label of choice for shipping and logistics labels but, for clarity, it’s important to understand that there are actually two different thermal labeling technologies.

- Generally speaking, when someone refers to thermal printer labels in the context of shipping labels, they are referring to direct thermal labels.

- Thermal transfer labels are the other type of thermal label. Thermal transfer label printing comes with its own unique advantages and disadvantages relative to direct thermal label printing. However, thermal transfer labels are rarely used as shipping labels and are best discussed separately.

This blog will explore direct thermal printed shipping labels specifically and describe the pros and cons of thermal printer shipping labels. We will also examine the push for BPA- and BPS-free labeling requirements and explain why BPA- and BPS-free thermal labels are such a hot topic in the logistics industry.

What is a Thermal Label?

What is a Thermal Label?

In the fast-paced world of logistics, there is a need to create shipping labels efficiently and cost-effectively. Thermal labels have emerged as a cornerstone technology, offering unbeatable versatility and value.

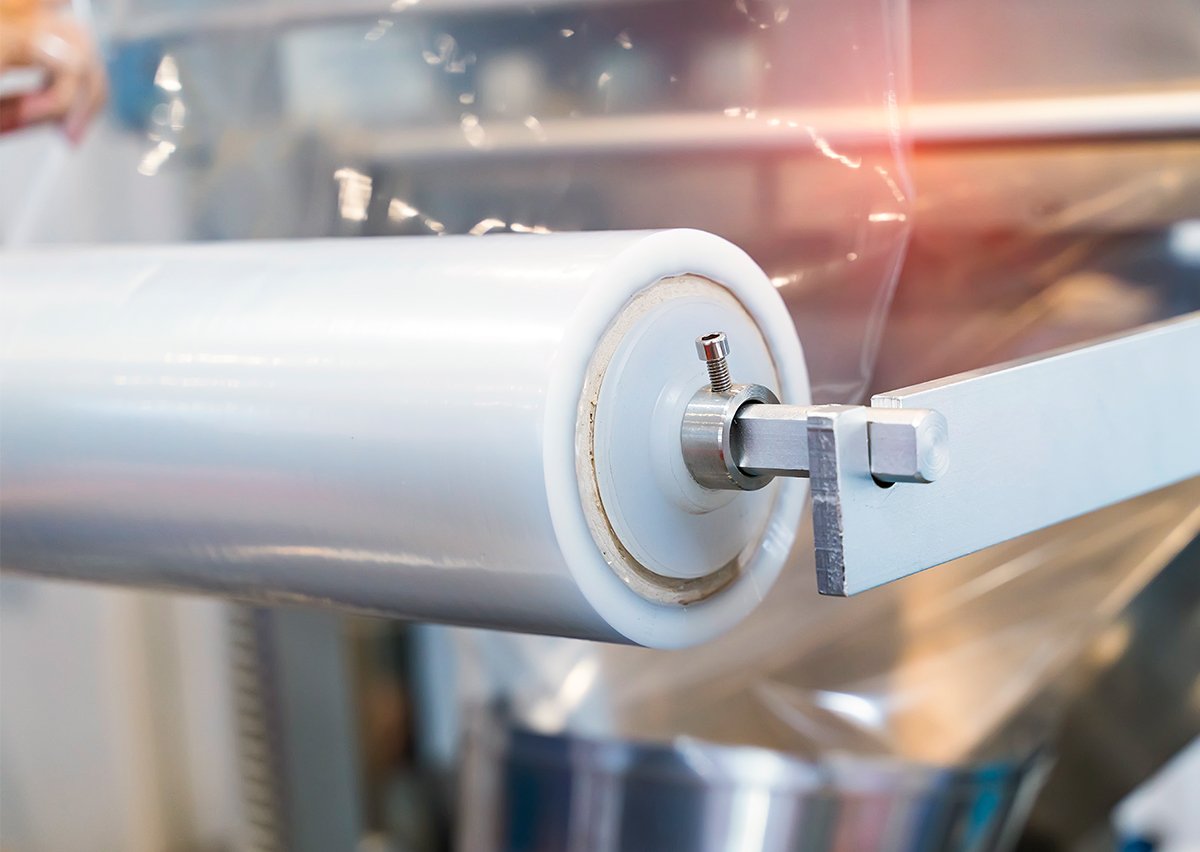

Direct thermal printer shipping labels utilize heat to create an image or text on the label surface. Compared to “traditional” printing methods, this type of thermal labeling is a highly cost-effective and low-maintenance solution. Direct thermal label printing is prized for its ability to deliver printed images quickly and efficiently — making direct thermal shipping labels the industry standard.

While heat is still part of the equation, thermal transfer labels are produced through an entirely different process. Thermal transfer label technology uses a ribbon coated with wax, resin or a combination of both. The printhead heats the ribbon, transferring the ink onto the label and helping it to bond with the label surface. This process generally offers enhanced durability, making thermal transfer labels suitable for long-term applications. However, thermal transfer labels are rarely used as shipping labels.

The Pros and Cons of Direct Thermal Printer Shipping Labels

Because direct thermal labels use a heat-sensitive layer on the surface of the label itself, this thermal labeling technology offers distinct pros and cons.

Direct Thermal Label Advantages

- Simplicity: There is no need for ribbons or ink, which reduces ongoing maintenance and operational costs.

- Speed: Fast printing speeds make direct thermal labels unbeatable for high-volume applications.

Direct Thermal Label Disadvantages

- Durability: Direct thermal printer shipping labels are susceptible to fading when exposed to heat, light or chemicals. If the item being labeled will encounter harsh environmental conditions, direct thermal shipping labels may encounter performance problems.

- Short-Term Use Only: Direct thermal printer shipping labels are best suited for applications where the label's lifespan is limited. If either readability or scannability (e.g., bar codes and QR codes) is required for more than a few months, direct thermal shipping labels may not be the best fit.

Common Uses

- Shipping Labels: As noted previously, direct thermal printer labels are, by far, the thermal labeling technology of choice for shipping and tracking purposes.

- Receipts: Direct thermal labeling technology is common in retail for printing receipts and transaction records.

- Barcode Labels: Direct thermal printer labels are also used for inventory and asset tracking — assuming environmental conditions and the label’s limited lifespan are taken into consideration.

What are BPA-and BPS-Free Thermal Labels?

No blog regarding thermal printing of shipping labels would be complete without a mention of phenols, including BPA- and BPS-free labeling requirements. Bisphenol A, or BPA, and Bisphenol S, or BPS, are chemicals found in a wide range of plastics, coatings and resins. Unfortunately, research has revealed that BPA and BPS may be absorbed through the skin and that exposure to BPA and BPS may pose a variety of health risks for humans.

What does this have to do with shipping labels? As it turns out, BPA and BPS can be present in certain types of thermal shipping labels. BPA or BPS in the label coating helps the paper to change color as it is heated and contributes to the crisp, darkly printed image. Because both BPA and BPS are now considered potentially hazardous chemicals, they are both subject to regulations such as California Proposition 65.

California Prop 65 and BPA- and BPS-Free Thermal Labels

Effective Dec. 29, 2024, all consumer goods made in or shipped into the State of California that contain either BPA or BPS must carry a Clear and Reasonable Warning as prescribed under Proposition 65. This regulation includes the shipping label on the outside of the package itself.

Washington State and Other Phenol-Related Regulations

It’s important to note that California isn’t the only state taking action on Bisphenols — and BPA and BPS aren’t the only phenols in question. The State of Washington requires special reporting related to the use of phenols, including Bisphenol F (“BPF”). Meanwhile, certain other states have phenol-related regulations based on product category. Violations of these regulations may result in significant penalties for the parties involved.

The Business Risk of Using Non-Compliant Thermal Shipping Labels

The business ramifications of the Bisphenol issue are clear. Regardless of geography or product category — or whether the chemical in question happens to be BPA, BPS or other phenol alternatives such as BPF — organizations that use thermal labels for shipping, tracking and asset management would be wise to take a closer look at the label materials they are using. Any business that utilizes thermal shipping labels should consult their compliance and legal teams to learn more and develop a plan that works for them.

Thermal Shipping Labels from Taylor

Taylor is a leading supplier of labeling solutions for all types of shipping, identification, industrial and consumer packaged goods (CPG) applications. This includes the thermal shipping labels described above.

Direct Thermal Printer Shipping Labels

Taylor’s direct thermal shipping labels feature ultra-white, high print contrast facestock for maximum printability and reliable error-free scans. We also offer the innovation of linerless direct thermal label stock, which reduces waste by eliminating the label liner that is ordinary thrown away.

BPA-Free and BPS-Free Thermal Shipping Labels

Given our standing as an industry leader, Taylor is proactively working with suppliers to transition to the use of only BPA- and BPS-free label substrates — in compliance with the California Proposition 65 requirements noted in this blog. Looking ahead, we are also working with our paper suppliers to identify thermal label materials that are entirely phenol-free as BPF, and other phenol alternatives, may be the next chemicals to face restriction in California and elsewhere.

See how Taylor’s materials science knowledge and expertise with custom packaging and labeling solutions can give your business a competitive advantage in the marketplace. Contact your Taylor representative to learn more.