After more than a year of pandemic-related challenges, the business climate is starting to thaw as people are finally able to work more, venture out more and spend more. Unfortunately, a supply chain crisis unlike any other in modern history is now creating cascading layers of customer disappointment.

Consumers are eager to buy but there’s no way to supply the goods and services they crave. What’s a marketer to do? In this post, we will explore how being planful and flexible can help mitigate the impact of the ongoing supply chain crisis, creating customer goodwill at a uniquely trying time.

Understanding the Supply Chain Crisis

The supply chain crisis now in full swing around the world can’t be traced to any one factor. It isn’t even due purely to the effects of the pandemic. Analysts agree that it is a problem many years in the making and with contributing factors compounding each other in a “perfect storm” of sorts. To fully grasp the severity of what’s happening, it’s helpful to look at a few of those contributing factors.

Crisis Factor #1: Raw material prices are up, supplies are down, lead times are longer

.jpg?width=698&name=Blog%20Body%20Image%20%E2%80%93%20Supply%20Chain%20(2).jpg)

In its most elemental sense, all manufacturing processes depend on raw material inputs. The supply chains for raw materials – whether refined from petroleum, mined, harvested or created in a laboratory – are almost universally under pressure in 2021. Prices are up, supplies are down, lead times are longer. As one of the largest graphic communications companies in North America, Taylor is particularly attuned to the raw materials consumed in the printing and graphics industry. Without paper and ink, we can’t print.

Here again, the supply chain crisis can be seen in nearly every major input. Wood pulp prices are up 33% year-to-date and are now at their highest levels in 20 years. Prices for finished paper stock have risen multiple times in recent months and are now up 15% in 2021. Worse yet, some materials are difficult to obtain at any price. Silicone resins used in the manufacturing of paper are in short supply, acrylic adhesives are on tight allocations from suppliers through the end of the year, and many grades of paper are likewise on allocation status from the mills.

Crisis Factor #2: Computer chip shortages are making consumer goods scarce

From mobile phones and microwave ovens to new cars and children’s toys, computer chips are a vital component of many consumer products. Alas, the current demand for computer chips is far outstripping the supply.

The emergence of 5G wireless technology and the countless millions of consumers working from home during the pandemic have conspired to elevate demand for computer chips. At the same time, global computer chip supply has taken a series of ill-timed hits. Many chip factories were closed for extended periods during the pandemic. Winter storms in Texas closed domestic chip factories in early 2021. A fire devasted a chip facility in Japan. The end result is a chip shortage that may last into 2023 and beyond according to IBM.

Crisis Factor #3: Global shipping costs and lead times are soaring

.jpg?width=698&name=Blog%20Body%20Image%20%E2%80%93%20Supply%20Chain%20(3).jpg)

One contributing factor to the rising prices and sparse availability of many items is the state of the global shipping industry. The pandemic cancelled countless sailings worldwide and labor shortages are bottling up ships in ports for days on end. As you read this, five dozen massive container ships are sitting at anchor outside the ports of Los Angeles and Long Beach. This pattern is being repeated around the world and mountains of shipping containers are sitting in all the wrong places.

Shipping costs, naturally, have soared to levels never seen before. The cost to transport a 40-foot shipping container from China to the U.S. recently hit $20,000, up 500% from one year ago. Equally problematic is the lost speed to market. The average time to ship a package from Asia to the U.S. is up 43% since last year, a problem expected to last until 2023. That delay looms large in regard to the customer disappointments noted above.

Crisis Factor #4: Ground transportation costs more and takes longer

The types of delays and constraints now playing out on the high seas can also be witnessed on America’s highways. The booming e-commerce industry, coupled with a shortage of truck drivers, has created an unsustainably high load-to-truck ratio. Long story short, it suddenly costs more and takes far longer to move a product from one point to another than it did just one year ago.

This particular issue was attracting notice long before the pandemic. Back in 2019, there was an estimated shortage of 60,000 truck drivers in the U.S. The demand for shipping has surged since then while thousands of drivers have taken early retirement, leading analysts to predict a shortage of 100,000 drivers by 2023. The shortfall is so acute that trucking firms are now scrambling to hire drivers from Mexico, Europe, South Africa and Canada.

Planning And Flexibility Can Ease Customer Disappointments

.jpg)

There’s no escaping the issue. Whatever you make or resell, you are potentially at risk of disappointing customers in the coming months with products that are either out of stock or delayed in delivery. However, with some foresight and flexibility, you can do a variety of things to mitigate the situation. Here are three things that you should be doing right now to ease customer disappointments during the supply chain crisis.

Make demand forecasting a priority

It’s possible that some of the items you depend on may be out of stock or backordered for an extended period of time. However, don’t be resigned to simply losing sales. Instead, put the power of data and analytics on your side.

Work with your marketing data team to understand what your customers have purchased in the past, in what quantities and at what times during the year. Are there patterns in the data that you may not have noticed before? Have you considered how your customers’ needs may have changed during the pandemic? How are your competitors weathering the storm? The more you know, the better your decision making will be.

Use this data to create a demand forecast looking at least three to six months into the future. Then, share this information with your most trusted vendor partners. Time is a precious commodity during a supply chain crisis. Each day of advance notice that you give a supplier increases the likelihood you will be able to source what you need, when you need it.

Set expectations proactively

Human nature is an interesting thing. More often than not, customer disappointments are fueled by unmet expectations rather than unmet needs. As long as people know what to expect well in advance, they are far more likely to be forgiving of delays and inconveniences.

Don’t make promises that you may have to break later on. Communicate early, often and honestly that your normal lead times may be unachievable. Then, commit to something you absolutely can deliver and set out to beat that expectation. In doing so, you’ll earn a reputation for underpromising and overdelivering – an enviable brand position in any industry.

Seek every opportunity to substitute

.jpg?width=698&name=Blog%20Body%20Image%20%E2%80%93%20Supply%20Chain%20(4).jpg)

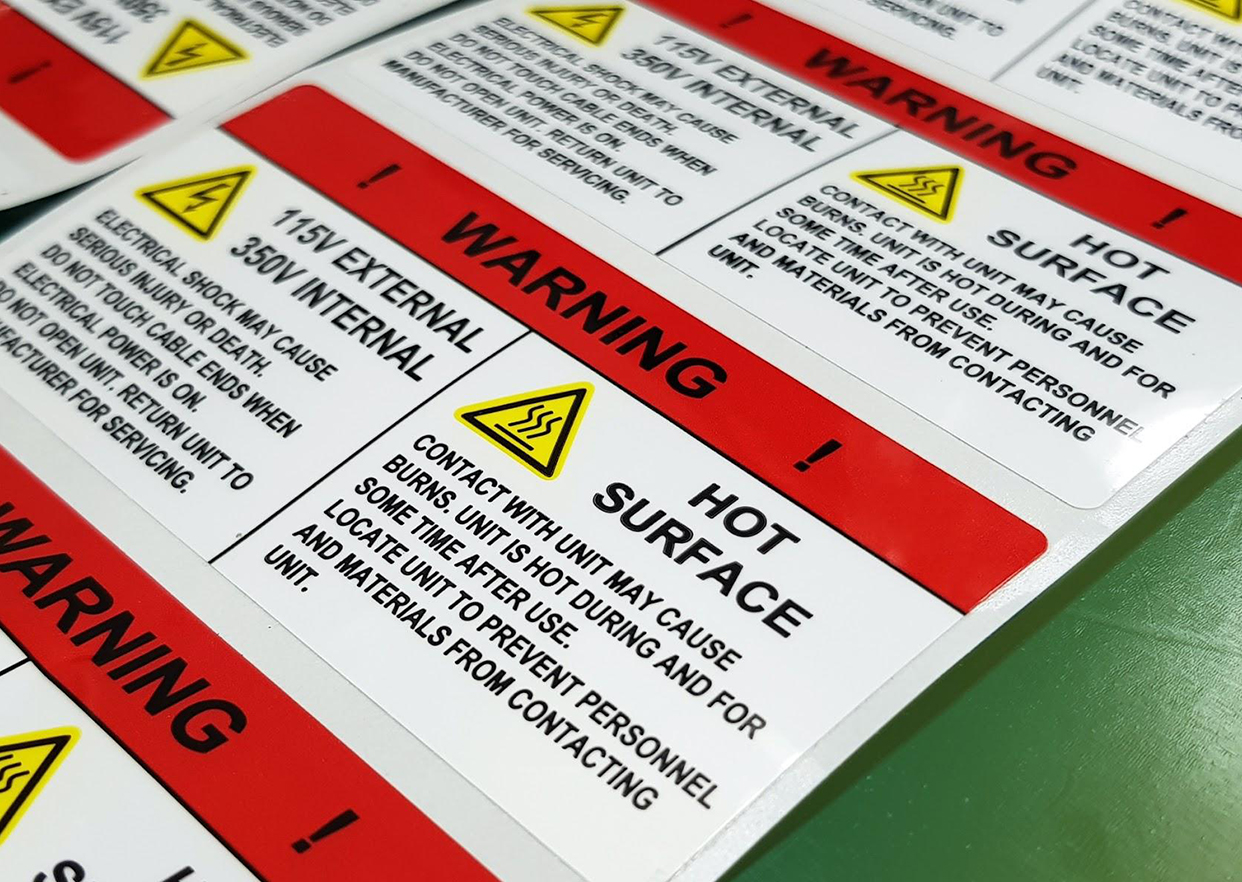

Flexibility is key in times of uncertainty. Work with your engineering, sales and marketing teams to determine if there are alternative products, feature sets or raw materials that will work “in a pinch.” You might determine that going to market with a 99% complete product now is better than waiting for a 100% complete product later on. For example, Cadillac recently made headlines by announcing that it would temporarily exclude the popular “Super Cruise” driver assistance system from its flagship Escalade SUV due to a computer chip shortage. Far better to have an Escalade with no Super Cruise than no Escalade at all. These types of substitutions are common in the graphic communications industry right now. Supply chain variability what it is, we often suggest alternative paper grades and raw materials that will enable our customers to stay on schedule and get to market quickly.

This same logic likely holds for your own product line and customers. Be open to substitutions from your suppliers and ask your customers to do likewise. An almost-as-good solution delivered on time will likely be warmly received – especially if you acknowledge the difference in your pricing.

The Supply Chain Savvy of an Industry Leader

As one of the five largest graphic communications companies in North America, Taylor knows a thing or two about global supply chains. We maintain a network of 78 production facilities across the nation and around the world, including six international warehousing or production sites. Doing so gives us added flexibility and reach during a supply chain crisis. It’s just one more reason why our customers look to Taylor to power their brands’ potential.