Something interesting happened in 2023 that suggests a profound shift is underway in the North American supply chain:

For the first time in two decades, the total value of U.S. imports from Mexico exceeded our imports from China.

As reported by The New York Times, the value of goods imported by the United States from Mexico topped $475 billion in 2023. Meanwhile, imports from China totaled $427 billion, a 20% dip from the prior year.

A number of factors drove these figures, including the increasing volume of automobiles being manufactured in Mexico — a high-value item that tends to skew the statistics. However, a key component of the shift can be tied to the “nearshoring” phenomenon that’s in full swing. This blog will explore the forces behind these nearshoring strategies and why Mexico is so attractive to manufacturers.

Nearshoring Defined

FreightWaves defines nearshoring as the relocation of manufacturing operations from one country to another to be closer to end consumers. Whereas reshoring involves the movement of manufacturing back to the “home country” of the company (i.e., the U.S. in this example), nearshoring moves the manufacturing to a neighboring country (such as Mexico).

However, manufacturers who have customers in the U.S. aren’t always based in the U.S. One of the first prominent examples of nearshoring in Mexico involved Daewoo Electronics in 1990. The Korean consumer electronics company built factories in Mexico to produce color TVs, VCRs and PCs, primarily for the U.S. market. That same model has been employed by companies from Japan, China and Europe.

Nearshoring in Mexico in Booming

In 2023, BBVA Research and the Mexican Association of Private Industrial Parks (AMPIP) conducted research to measure the impact of nearshoring on the Mexican economy and to forecast its impact in the coming years. The findings were startling:

- Approximately 75% of the companies hosted by AMPIP’s industrial parks are foreign companies operating in Mexico.

- Between 2018 and 2023, 830 new foreign firms were “received” by AMPIP’s industrial parks.

- In 2024-2025, AMPIP expects to receive another 450+ companies to its industrial parks.

The 3 Reasons Why Nearshoring Works

Clearly, manufacturers who have their sights set on the U.S. market find nearshoring to Mexico an attractive strategy. There are three primary reasons why.

1: Physical Proximity to the U.S. Market

The shipping bottlenecks experienced during COVID-19 taught manufacturers a painful lesson. Compared to shipping goods across the ocean from China, Japan, Korea or elsewhere in Asia, transporting goods from Mexico is comparatively simple.

Colliers notes that there are more than 50 border crossings along the 2,000-mile U.S./Mexico border; no ocean crossings necessary. This enables products to reach U.S. customers in as little as 3-5 days versus 15-50 days when shipping by sea from Asia.

2: Lower Labor Costs, Better Talent Availability

Labor is both easier to come by and less expensive when compared to the U.S. According to Forbes, skilled machinists and welders earn between $7 and $8 per hour in Mexico. The same skillset in the U.S. — if it can be found at all — will command $20 or more per hour.

Colliers also notes the demographic trends that have transformed Mexico’s talent pool. Citizens there have an average age of just 29 years, nearly 10 years younger than their counterparts in the U.S. As American Baby Boomers continue to retire in waves, the talent pool in Mexico becomes increasingly attractive. Likewise, Mexico’s education system, technical training programs and English proficiency result in a workforce that is attractive to automotive, aerospace, high-tech and other industries.

3: Favorable Trade Agreements

The United States-Mexico-Canada Agreement (USMCA) superseded the North American Free Trade Agreement (NAFTA) in 2020. The USMCA creates a more level playing field for American workers while simultaneously easing the flow of goods across the partner countries.

One key benefit of the USMCA to manufacturers involves duties and tax incentives. Under the USMCA, qualified products can be imported to the U.S. from Mexico without incurring duties or taxes — a cost-savings that can change the economics of going to market in the U.S. This is on top of the efficiencies gained through fast, ground-based transportation and the availability of skilled labor at lower hourly rates.

There is also the matter of geopolitical uncertainty. Chilly, unpredictable relations with China make offshore manufacturing there risky. Meanwhile, the United States’ relationship with Mexico continues to be friendly and stable.

Label Manufacturing That Supports Nearshoring in Mexico

In April 2023, Taylor opened a state-of-the-art label manufacturing facility in Monterrey, Mexico. Covering 107,000 square feet, Taylor’s Monterrey facility consolidates all aspects of production, warehousing and distribution under one roof. It is ideally suited to the durable industrial label needs of automotive, HVAC and electronics manufacturers in Mexico.

In April 2023, Taylor opened a state-of-the-art label manufacturing facility in Monterrey, Mexico. Covering 107,000 square feet, Taylor’s Monterrey facility consolidates all aspects of production, warehousing and distribution under one roof. It is ideally suited to the durable industrial label needs of automotive, HVAC and electronics manufacturers in Mexico.

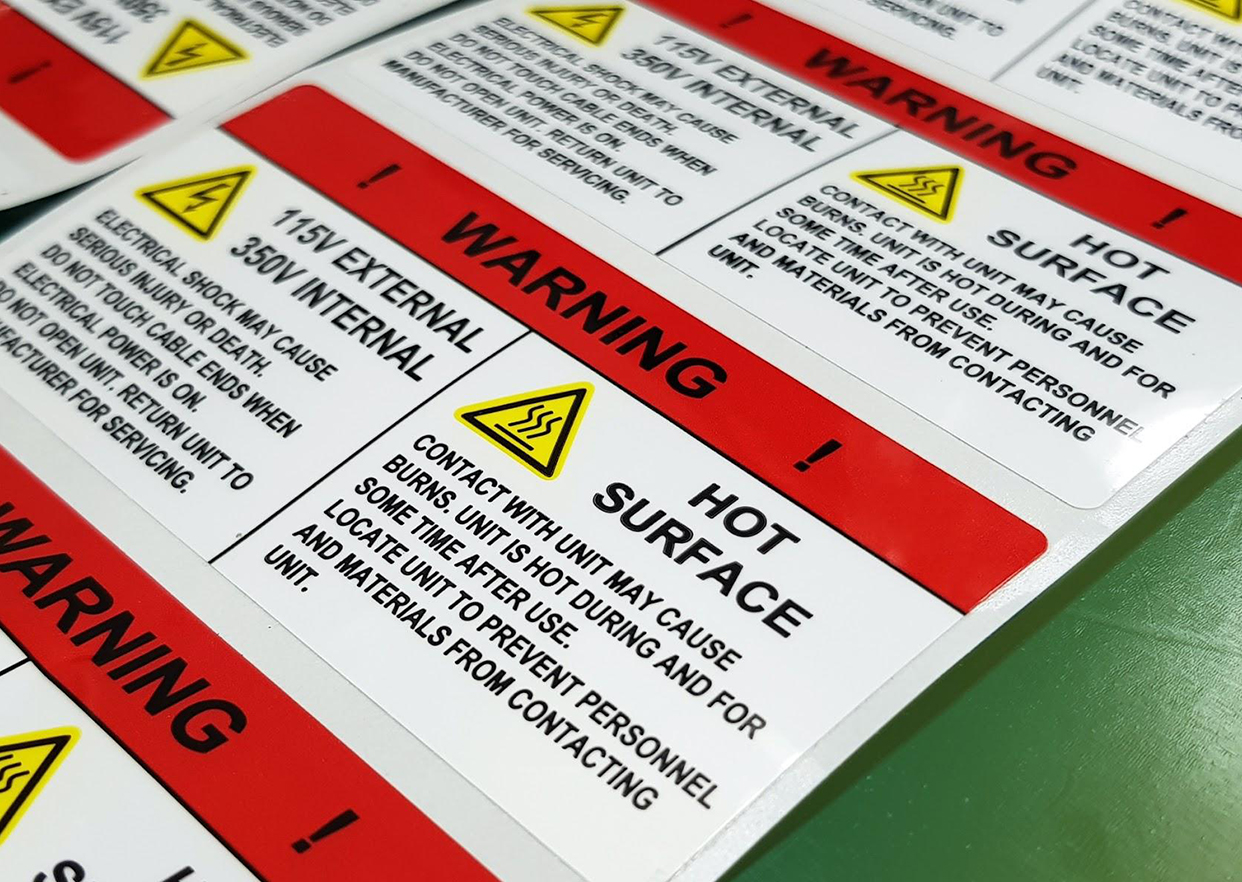

Taylor’s diverse range of capabilities in Monterrey include:

- Label production using digital, flexographic, eight-color process and screen printing technology that “mirrors” the technologies of similar Taylor facilities in the U.S.

- Technical literature production, kitting, inventory management and process enhancement services.

- Comprehensive regulatory and compliance expertise relevant to both the U.S. and Mexico, encompassing standards such as UL, ANSI, and CSA.

- Certifications and best practices including ISO 9001:2015, IATF 16949, ISO 14001:2015, SGS and WCA.

- Bilingual customer support teams that ensure a seamless experience for manufacturers doing business in both the U.S. and Mexico.

- Access to additional Taylor warehousing and distribution facilities in Cd. Juarez, Mexicali, San Luis Potosí and Tijuana.

See how Taylor’s mirrored U.S.-Mexico label production model supports manufacturers with nearshoring operations in Mexico. Contact your Taylor representative to learn more.