Thus far on our tour of the 4 P’s of Printing, we’ve looked at printing paper and the two types of processes most commonly used in commercial printing. This time, we dive a bit deeper and look at the printing presses themselves. Our four-part blog series will then conclude with a look at the basic types of printed products most commonly created for marketing purposes.

Printing Presses Compared

Since the Gutenberg press roared onto the scene in 1450, humans have devised a number of ingenious ways to transfer ink onto paper. Here are the types of printing press technologies you are most likely to encounter when sourcing print services.

Letterpress

The letterpress is the oldest printing technology in existence. Artwork and text are converted into a rigid material such as metal. The raised surfaces are then coated with ink and “pressed” onto the paper.

Printing done via letterpress offers many advantages. It results in a high-quality, handcrafted look with a slight impression or debossing where the ink was laid onto the paper. A letterpress is the quintessential printing press for business cards and letterhead stock. It is also environmentally friendly as the inks used are typically water based.

On the downside, printing via letterpress is labor intensive and comparatively slow. If you’re in need of a higher volume of output, you will likely find other methods to be faster and more cost-effective.

Flexography

A flexographic or “flexo” printing press is essentially a modern interpretation of the letterpress. However, it is engineered for volume and speed.

With flexo printing presses, a flexible photopolymer printing plate is attached to a rotating cylinder. Similar to a letterpress, only the raised surfaces of the printing plate are inked. The print substrate is then fed between an impression cylinder and the inked plate cylinder, resulting in the ink being transferred to the substrate.

Flexo printing presses offer the advantage of being able to print on a wide range of materials beyond paper. Plastic, foil, paperboard cartons, flexible packaging materials and more can be printed at high speed using a flexographic printing press. Flexo presses also accommodate eco-friendly, fast-drying water-based printing inks.

On the other hand, flexographic printing is not as precise as other printing technologies. Intricate, highly detailed images can generally be reproduced more clearly using other types of printing presses. Setup times and setup waste are also high, as are the costs of the printing plates used. For these reasons, flexo printing is most commonly used in the consumer packaged goods industry for high-volume items like product labels and packaging.

Offset lithography

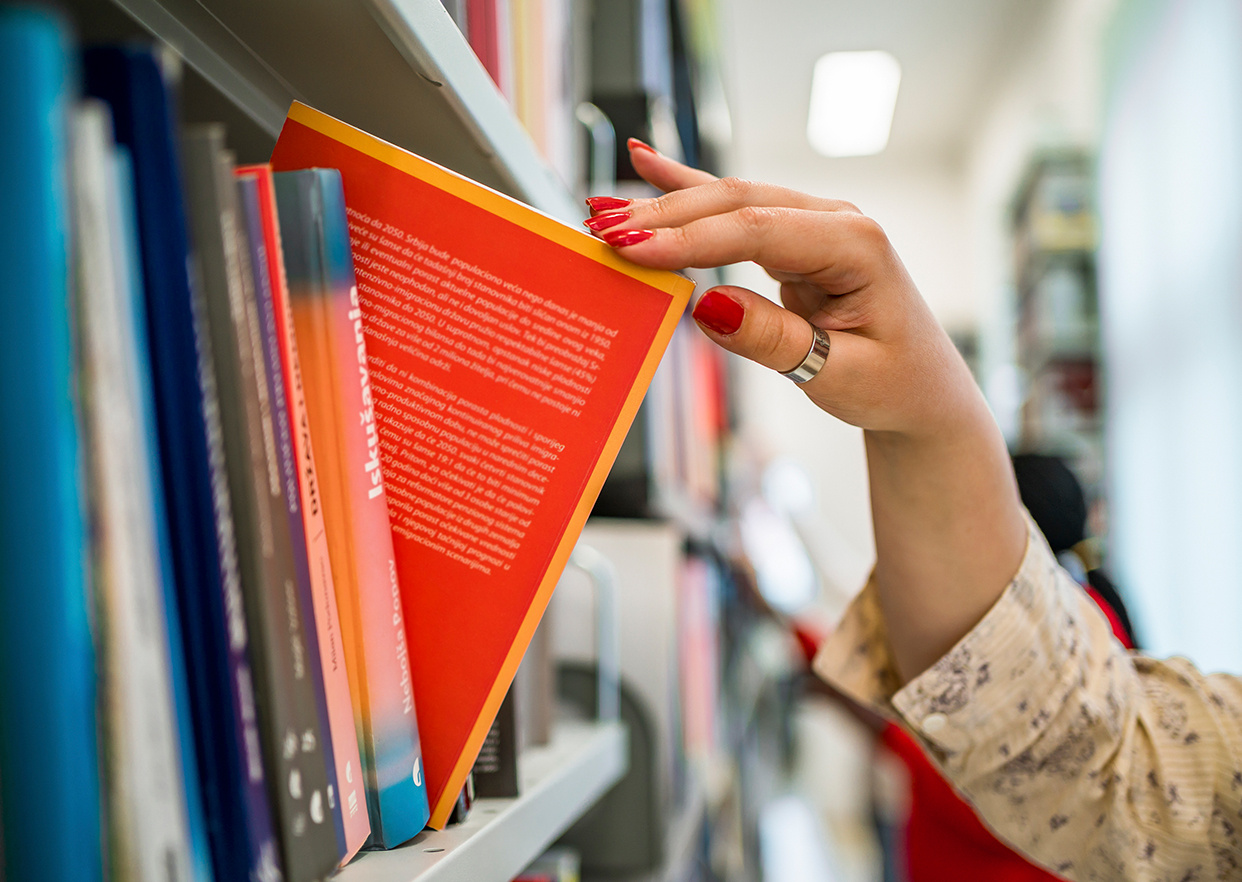

Offset lithography and flexography are similar in that ink is applied to a printing plate. However, with lithography, the ink from the printing plate is first transferred to a rubber blanket and then to the print substrate. Thus, with lithography, the printing plate never comes into direct contact with the print substrate itself.

When used to produce large quantities of materials, offset lithography is an economical print technology for things like books, brochures and magazines. It reproduces images clearly and is particularly well-suited to print materials that involve large amounts of text.

Then again, setup of a litho print job is complex and time-consuming. When the cost of plates and cleanup between jobs is added in, offset lithography is generally economical only for large print runs – assume 5,000 to 10,000 pieces and up depending on the press. It is also requires the use of oil-based inks and solvents, making it less environmentally friendly.

Digital printing presses

A digital printing press functions much like the color printer in your home office, only on a larger scale and at a faster speed. Unlike a letterpress, flexo press or offset litho press, there is no physical plate to transfer the print impression onto the print substrate. Rather, the image is directly transferred to the substrate either through the spraying tiny ink droplets or the fusing of toner onto the surface using heat.

Digital printing presses require no printing plates and virtually no setup or cleanup between print jobs. This makes them faster and more cost-effective for smaller print runs, such as projects that are not economical for offset lithography (see above). Digital printing presses also consume no water, produce little waste and are very environmentally friendly.

Finally, a digital press also has the advantage of being fully digital in nature. Things that are impossible on a litho or flexo press – like variable messaging, 1:1 personalization and data-driven artwork – are child’s play for a digital printing press. All of these advantages stack up to make digital printing presses the technology of choice for fast-turn, low-volume print runs or wherever customization/personalization is required.

In terms of negatives, digital printing presses are not (yet) able to reproduce color as accurately as a traditional ink-based printing process. They also cannot reproduce metallic effects and opacity can be an issue depending on the print job. If the printed item requires precise reproduction of a signature color, you would be advised to explore one of the “older” printing technologies described above.

A Word About Print Finishing

Printing is about much more than just ink or toner. Various other steps may be incorporated to produce the finished printed piece.

.jpg?width=1455&height=626&name=Blog%20Body%20Image%20Second%20%E2%80%93%20Print%20101%20Series%20(3).jpg)

Die-cutting

A die is a thin, razor-sharp steel blade that allows multiple pieces of paper to be formed into a specific shape. Custom dies can be used to shape the entire piece, create perforations or cut elaborate shapes from within the printed piece.

Embossing and debossing

Embossing uses a metal die to raise the surface of the paper. Debossing uses a similar die to recess the image into the paper. These techniques can be done “blind” without the use of ink, or registered in harmony with a printed color in the raised or recessed surface.

Foil stamping

Heated metal dies can be used to apply shiny foil to paper, creating an elegant look. The bright, reflective effect of foil allows designs and messaging to be imprinted on top of dark paper stocks.

Spot matte or gloss

Harkening back to our prior blog about the spot color printing process, high-gloss and matte-finish coatings can be applied over the top of a printed piece in precise locations to create eye-catching visual effects. It is ideal for drawing added attention to a specific area.

The Best Printing Press Technology

There are many printing technologies in use today and each has its strong points.

- A letterpress creates a high-quality printed image ideal for low-volume print runs such as business cards and letterhead.

- The speed and flexibility of the flexographic press make it the printing technology of choice for product packaging.

- The image quality and clarity of offset lithography make it unbeatable for things like magazines and books – but only if the print volume justifies the high setup costs.

- Digital printing presses are quick to set up, environmentally friendly, allow 1:1 personalization and make small production runs economical. However, they cannot produce color as accurately.

- Print embellishments like die-cutting, embossing, debossing, foil and spot coatings complement the printed image to create effects that no single print technology could deliver on its own.

Printing Blog Series Continues

The final blog in our 4 P’s of Printing series will look at printed products most commonly used for marketing communications applications.

Taylor: All Major Print Technologies in One

.jpg?width=1455&height=626&name=Blog%20Body%20Image%20%E2%80%93%20Print%20101%20Series%20(3).jpg)

Taylor knows that no two print jobs are exactly alike. That’s why we’ve invested in one of the largest and most technologically advanced fleets of printing presses in North America. All of the print and finishing technologies noted above – and more – are offered through Taylor’s vast print production network:

- Die-cutting

- Digital print-on-demand

- Embossing and debossing

- Flexography

- Foil stamping

- Letterpress

- Lithography

- Spot matte and gloss

- Thermography

To learn more about Taylor’s printing and finishing technologies, please contact one of our print experts.