Tier 1 and Tier 2 diversity spend tracking is a growing priority in healthcare as hospital supplier diversity becomes a strategic focus.

Streamline your warehousing and fulfillment operations

with a single partner for all your inventory management,

logistics, kitting, print on demand and cold chain services.

“After searching for over a year for a solution, I was pleased with the outcome of this project. The timeline was met, the team was knowledgeable and open to new ideas on how to improve the experience.”— CVS Health / AETNA

Warehousing is the storage, inventory management and distribution of your

products. It is made up of the facilities and processes used for storing your products

before they are sold or shipped.

Fulfillment takes a higher level view. It encompasses all the processes you use for

producing, receiving, processing and delivering orders to customers and clients.

Warehousing provides you with centralized locations for storing your products, usually for an extended period of time. In addition to storage, they’re your hubs for receiving new and replenishing existing inventory, and streamlining shipping and distribution.

For organizations with large or complex inventories, handling warehousing on your own can be a daunting task. There often isn’t enough space on-site or personnel to handle shipping, receiving and all the other processes that come with operating your own warehouse.

Even outsourcing your warehousing operations can prove difficult. If you’re using multiple warehousing partners to store your products, simply managing the different processes for each vendor can be a drain on your time and resources.

1.7MIL

square feet of warehousing

space in the U.S.

99.3%

order shipment accuracy rate

Fridley, Minnesota

Taylor Facility | 75,000 sq ft

Grove City, Ohio

Taylor Facility | 296,000 sq ft

Jeffersonville, Indiana

Taylor Facility | 242,377 sq ft

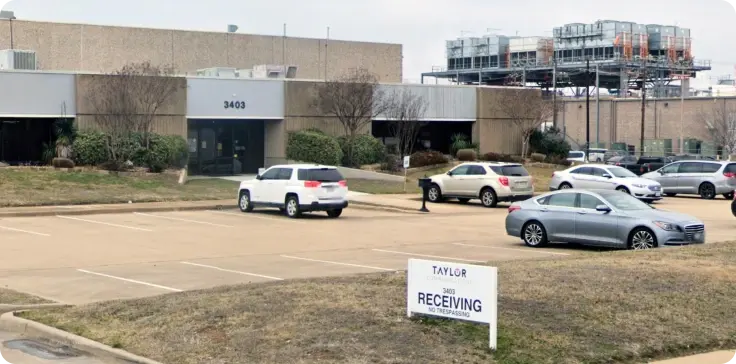

Dallas, Texas

Taylor Facility | 241,954 sq ft

Cranbury, New Jersey

Taylor Facility | 188,000 sq ft

Atlanta, Georgia

Taylor Facility | 115,000 sq ft

Omaha, Nebraska

Taylor Facility | 75,000 sq ft

Lakeland, Florida

Taylor Facility | 70,000 sq ft

Avon, Massachusetts

Taylor Facility | 50,000 sq ft

Fresno, California

Taylor Facility | 35,000 sq ft

Seattle, Washington

Taylor Facility | 40,000 sq ft

Phoenix, Arizona

Taylor Facility | 94,000 sq ft

Crystal Lake, Illinois

3PL PARTNER

Indianapolis, Indiana

3PL PARTNER

Pittsburgh, Pennsylvania

3PL PARTNER

Wilkes-Barre, Pennsylvania

3PL PARTNER

Raleigh, North Carolina

3PL PARTNER

Carolina, Puerto Rico

3PL PARTNER

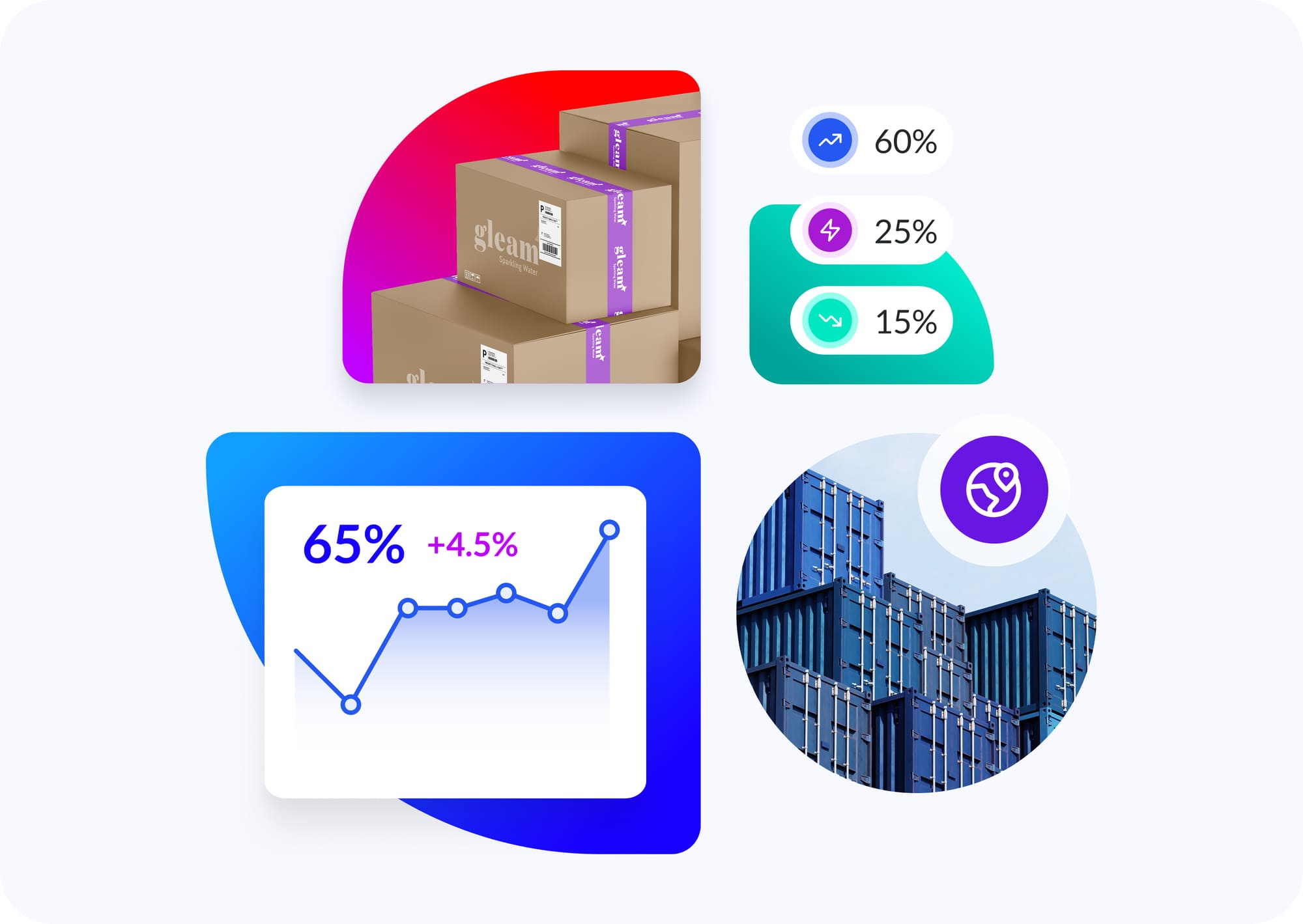

The best way to ensure your warehousing operations run smoothly is to consolidate your storage with a single warehousing partner. This will improve the flow of your products and goods throughout your supply chain, and increase efficiency when it comes to order fulfillment.

Working with a third-party logistics (3PL) partner for your warehousing needs, it makes managing your inventory easier, allowing you to respond to changes in demand and improve customer satisfaction. That’s why choosing the right warehousing partner makes all the difference.

Warehousing should be seen as a strategic piece of your overall business operations. Your

warehousing is another opportunity to strengthen customer experience, enhance your

organization’s efficiency and ultimately improve your profitability.

Reduce shipping costs and one-day shipping to most major markets.

Online platform customized for your

business.

The ability to delegate inventory monitoring to your account management team.

A robust database that houses the metrics you need to make informed business decisions.

Taylor is a leader in warehousing and distribution with state-of-the-art

capabilities and fulfillment and distribution centers across the country.

13

warehousing and

fulfillment facilities

1-day

coverage to most major

U.S. markets

5.3 MIL

orders fulfilled

annually

Fulfillment centers give your business the resources to quickly fulfill orders and deliver them to your customers. They also specialize in branding, packaging and shipping options that reflect your company’s image and messaging.

Relying on in-house fulfillment or multiple fulfillment partners for different product categories takes time and money that could be spent on developing new products, marketing campaigns and more objectives to grow your business.

Using a single partner for your fulfillment solutions and services removes these burdens. Third-party fulfillment centers are set up to handle the entire order fulfillment process for your company.

Fulfillment centers utilize state-of-the-art technology to accurately produce and distribute your products, and give you logistics advantages that lead to cost-effective and timely distribution.

This also includes order picking, packing and shipping, and all other logistics processes that serve to get a product from seller to customer.

When you work with an expert fulfillment partner, your organization will be able to rely on a

fulfillment center tailored to your distribution needs, and the time and money previously

spent on space and equipment can be redirected to other parts of your business.

Fulfillment centers can also be used when you’re not using any on-hand inventory. Taking a print-on-demand approach to print fulfillment keeps you from overspending on unused items, and reduces the costs that come with obsolescence and waste.

Print fulfillment centers make it easy to merge your print-on-demand items and your inventory products all in one place.

Taylor’s print-on-demand facilities make up North America’s largest print-on-demand footprint, offering a wide range of products, including stationery, wall art, gifts, décor, packing and more.

In the same way omnichannel communications allow you to reach your customers in their

preferred communication channel, omnichannel fulfillment allows your customers to find, order

and receive items in their preferred sales channel.

Partnering with a single fulfillment partner allows you to centralize the storage and distribution

of your physical inventory and the production of your print-on-demand items.

Omnichannel fulfillment seamlessly integrates all the sales channels your company uses.

Instead of siloed areas, your organization will be able to provide customers with a consistent buying experience regardless of where and when they do their shopping.

Omnichannel fulfillment allows you to fulfill orders using a combination of channels.

Product kitting is the assembly of a collection of individual products into a custom package or kit constructed with a specific preference or customer in mind. Kits can be put together through manual or automated processes, depending on the complexity of the final product.

The kitting process adds another layer of complexity to the in-house warehousing and fulfillment strategy. If the day-to-day packing and shipping of individual products stretches your resources thin, then kit assembly is likely not a task you have the time or money for.

Kitting can be even more difficult with multiple vendors producing them. When your products are in the hands of several different suppliers, it is very hard to guarantee your brand is properly represented every time.

Partnering with a third-party kitting and fulfillment vendor that provides custom

kitting is the solution to these issues.

Relying on a single kitting partner eliminates the hassle of working with multiple

suppliers, and allows you to reorient the resources you would be using for in-

house kitting back to core business priorities.

Taylor assembles and delivers more than 27 million kits each year

Industry-leading technology that allows for scalability and flexibility

Customize materials by location-specific needs and customer demographics

Partnering with a third-party kitting and fulfillment vendor that provides custom kitting is the solution to these issues.Relying on a single kitting partner eliminates the hassle of working with multiple suppliers, and allows you to reorient the resources you would be using for in-house kitting back to core business priorities.

Your kitting provider takes on all storage responsibilities. This saves not only what you would spend, but also the space that would need to be used to house your products.

When you do your kitting in-house, you can only ship from one location. A kitting partner gives you strategically located distribution centers that reduce both shipping time and cost.

A kitting and fulfillment partner will have entire teams dedicated to the fast and accurate kit assembly for your company.

As demand for certain products rises and falls, you might need to order more than you can store. Working with a kitting provider gives you the space, speed and flexibility to adjust with the market.

Another area where a kitting provider can stand out is with custom packaging. Packaging, labeling, wrapping and more can be fitted based on specific customer and location needs.

Your kitting partner will have the tools to offer customer personalization that in-house kitting can’t match. This will increase customer satisfaction and loyalty, and lead to more sales.

Cold chain fulfillment is the safe storage, packaging and delivery of temperature-sensitive products for both the pharmaceutical and retail industries. The storage and packaging solutions you choose for your company’s temperature-sensitive items are critical to ensuring they arrive in top condition, and meet the regulatory requirements of your industry.

Cold chain distribution is extremely difficult to do in-house, and using multiple vendors to store and ship products that require temperature consistency is not much easier.

When your cold chain solutions are spread out across several suppliers, you run into issues with delivery intervals, lapses in package design and other best practices, and the availability of eco-friendly packaging options.

As a cold chain fulfillment partner, we give your company the specialized cold chain packaging and logistics resources you need to ensure your temperature-sensitive products are stored and delivered as intended.

Reliable cold chain solutions are critical for the pharmaceutical industry. Temperature-sensitive products such as prescription drugs, vaccinations and inhalers require a temperature-controlled environment all the way from manufacturing to use by the recipient.

When you work with an expert in pharmaceutical cold chain packaging, your organization will have the benefits of secure and efficient cold storage, packaging and shipping.

The need for temperature control is not just essential for pharmacies. The retail and food industries also require cold chain storage and distribution for certain products.

Keeping retail and food products at their optimal temperatures maximizes both freshness and shelf life.

Taylor is a leading provider of cold chain distribution services.

Tier 1 and Tier 2 diversity spend tracking is a growing priority in healthcare as hospital supplier diversity becomes a strategic focus.

.jpg)

RFID technology has spawned countless innovative RFID logistics solutions as industries realize the benefits of RFID in supply chain management.

Stay up to date with Taylor’s quarterly newsletter detailing the latest industry news, supply chain markets, and the pricing of goods and services.

Stay up to date with Taylor’s quarterly newsletter detailing the latest industry news, supply chain markets, and the pricing of goods and services.

Stay up to date with Taylor’s quarterly newsletter detailing the latest industry news, supply chain markets, and the pricing of goods and services.

Taylor streamlined a major pharmacy chain’s cold chain logistics, standardizing supplies, reducing costs, and improving efficiency for pharmacists nat...

Stay up to date with Taylor’s quarterly newsletter detailing the latest industry news, supply chain markets, and the pricing of goods and services.

Taylor's cold chain solutions ensure safe, efficient storage and distribution with sustainable materials and extensive logistics

Stay up to date with Taylor’s quarterly newsletter detailing the latest industry news, supply chain markets, and the pricing of goods and services.

Companies are demanding more sustainable packaging, including recyclable and reusable cold chain packaging materials used in cold chain distribution.

Taylor has been Rifle Paper Co.'s trusted partner for nearly a decade, providing G7® certified printing, warehousing, and custom kitting for their vib...

Stay up to date with Taylor’s quarterly newsletter detailing the latest industry news, supply chain markets, and the pricing of goods and services.

Warehousing involves the physical storage of goods for a period of time so they can be used at a later date for some other purpose. Items are received at the warehouse and held there until ready for the next link in the supply chain. Security systems, loss prevention procedures and climate control are key considerations when evaluating a warehouse facility.

The key difference between a warehouse and a fulfillment center is the manner in which orders are processed. While stored items can be shipped from both a warehouse and fulfillment center, fulfillment centers also process and prepare other types of orders for delivery to the customer. This can include custom packaging, product kitting, print on demand and other services.

Third-party logistics is the name given to companies that provide outsourced logistics services for their clients. There are many types of third-party logistics companies but the common theme is that they all provide some form of outsourced logistics services to their clients. Whether they provide the service themselves and/or outsource those services from another provider on behalf of their client.

The key to 3PL providers — and what sets them apart from 2PL providers — is integration. A third-party logistics partner is integrated into their client’s business and functions as a seamless extension of the client’s own operations. A second-party logistics provider is typically involved in moving goods from Point A to Point B. Thus, a 2PL is someone you hire situationally to move an item while a 3PL is someone you form a close and long-term working relationship with to turn warehousing and fulfillment operations into a competitive advantage.

While order fulfillment centers provide both kitting and packing services, they are two distinct processes.

Product kitting is the gathering of individual items or components and grouping them together as a single product - this is what’s referred to as a “kit.” The main purpose of kitting is to create bundled products to be sold. The kitting process is also used to streamline product assembly after the sale for the customer and simplifies inventory management for the vendor.

Packing is the process of putting items into packaging materials (such as boxes, cartons, bags or containers) for shipment and storage. The main goal of packing is to ensure items are protected during transit, that they are stored safely and ready for delivery when ordered. Packing can include single products or multiple orders placed into a single shipment.

Cold chain warehousing and distribution encompasses all phases and the management of the cold supply chain, including the shipping, storage and distribution of temperature-sensitive products. Temperature-sensitive products that require cold chain management solutions include pharmaceuticals, vaccines, lab samples, diagnostic materials, chemicals, and certain foods and beverages. Cold chain management is crucial for product safety and adhering to regulatory requirements.

Cold chain logistics requires a cold chain fulfillment partner with knowledge and control of temperature-controlled storage and shipping environments, temperature-sensitive packaging design, transportation modes, delivery intervals and other critical control points.

Omnichannel fulfillment is the ability to provide your customers with the ability to order your products in their preferred channel, be it the brick-and-mortar store, online, and via mobile devices and social media.

Being able to accept and deliver orders in multiple channels and provide a seamless customer experience in each can lead to many benefits for your business.

Customers can choose how and where they shop, and how they receive their orders. This includes buying online and in-store or curbside pick-up.

When your business sells through multiple channels, you can broaden your reach and grow your customer base. Cross-selling and upselling opportunities also increase.

Utilizing your inventory across multiple channels can reduce overstocking and improve turnover rates. Increased visibility to your inventory also helps prevent stockouts.

The options provided to customers by omnichannel fulfillment can make your business stand out from your competitors. This leads to improved customer satisfaction and in turn leads to increased customer loyalty.

Fields marked with an asterisk (*) are required.