Custom Packaging & Labeling Solutions

Communicate with labels and packaging.

Bring your products to market with packaging and labeling solutions created specifically for you and your business. The right label, carton or package can make all the difference.

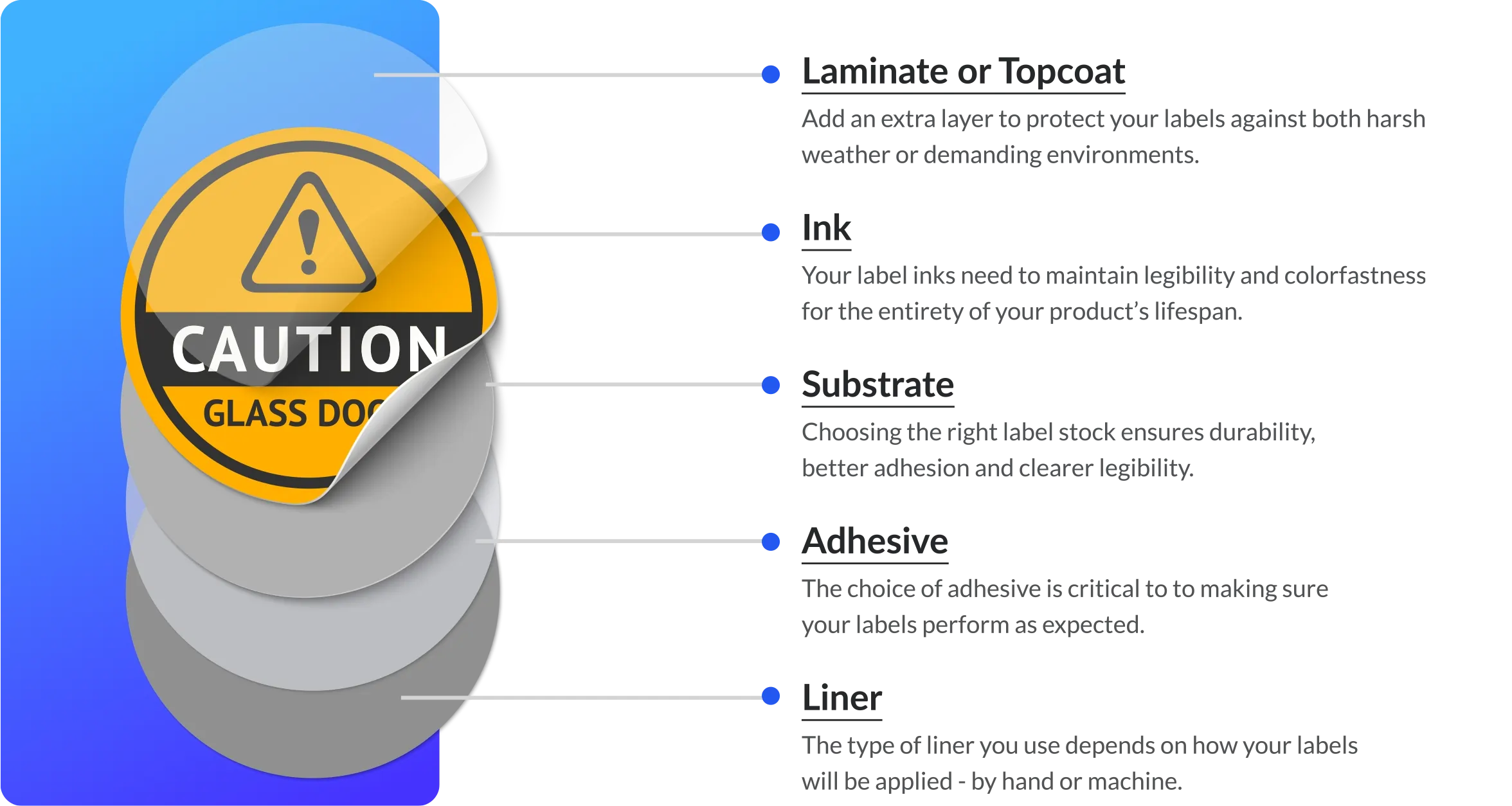

The Importance of Label Manufacturing

Labels shape the customer experience with your product. Choosing the right components means everything when it comes to performance, aesthetics and conveying information.

1. Laminate or Topcoat

Add an extra layer to protect your labels against both harsh weather and demanding environments.

2. Ink

Your label inks need to maintain legibility and colorfastness for the entirety of your product’s lifespan.

3. Substrate

Choosing the right label stock ensures durability, better adhesion and clearer legibility.

4. Adhesive

The choice of adhesive is critical to making sure your labels perform as expected.

5. Liner

The type of liner you use depends on how your labels will be applied - by hand or machine.

Levels of Product Packaging

Labeling Solutions

Cartons and Flexible Package Printing

Made to be memorable and build brand recognition. Showcase your products in the marketplace.

Labeling Programs

Engineered to be dependable and compliant. Increase efficiency and eliminate line-down risks.

Digital Label Solutions

Labels are no good sitting in a warehouse waiting on their expiration date. Printing labels digitally reduces waste, obsolescence and the aging of materials – and sometimes the need to warehouse material at all.

You can order your labels as needed with digital on-demand production.

Integrated Labeling

Sometimes less is more. When labels have to serve multiple purposes, it can be easy to start adding and adding until the entire document become too complex. Integrated labels are designed to simplify things by combining forms and labels or two labels of different materials.

Doing so streamlines the production process, decreases matching errors and saves you money.

In-Mold Labeling

In-mold labeling (IML) is the process of decorating a product with a label or design during the molding process. It can be used in retail and other indoor applications as well as outdoors in harsh environments.

Stock Labels

There are always times when it’s best to use a stock labeling solution to keep costs down and speed up delivery. When these occasions arise, having an easy-to-order program ready to use is a great advantage.

Taylor’s stock label program has everything you need when you’re trying to save money or beat the clock.

Take control of your

packaging and labeling.

Stop chasing down orders and quotes from multiple vendors. Download our white paper and see how consolidating your packaging and labeling programs gives you centralized control.

Toro Saves $25,000 with Lower Scrap Rates

Grafilm® IML Technology Enhances Quality and Reduces Costs

Toro was experiencing high scrap rates and long cycle times with their in-mold labels. Production costs were going up and manufacturing was slowing down.

Switching to Taylor’s Grafilm IML process drastically reduced Toro’s scrap rate.

Improved performance and durability meant a better, longer-lasting label.

The IML solution allowed Toro to shorten their cycle times and enhance efficiency.

Packaging and Labeling Resources

Your source for success stories, design and engineering tips, and all things packaging and labeling.

Related Packaging and Labeling Solutions

Create lasting customer experiences with our award-winning services and solutions.

Commercial Print

Packaging and labeling deliver your brand’s message, values and initiatives just like your flyers, brochures and other campaign materials.

Learn moreCold Chain Storage & Distribution

When temperature is a factor, custom refrigerated packaging and labeling solutions are crucial to warehousing and shipping.

Learn moreSigns, Graphics & Brand Experiences

Execute your brand strategy with packaging and displays that perfectly convey your message and mission.

Learn moreFrequently Asked

Questions

How can Taylor help us with our packaging and labeling programs?

Taylor understands the vital role that labels play in a production process. Companies in a wide range of industries have entrusted their labels to Taylor for more than 100 years — and with good reason. Our team of labeling experts works closely with clients to identify the specific performance requirements of each label and then recommends ways to improve label performance, reduce obsolescence, lower total costs and enhance operational efficiencies. When combined with Taylor’s technologically advanced production network, we are able to deliver a comprehensive labeling solution that creates operational efficiencies and eliminates line-down risk.

How does Taylor go about identifying performance requirements?

Taylor has a well-documented process called MAP3 (for Methodical Assessment of Printed Parts and Processes) that lowers the total cost of label ownership and reduces risk by increasing compliance with industry labeling regulations.

Our highly trained team of technical consultants will analyze the fit, form and function of all printed production parts with the goal of driving cost reductions via a number of process improvements. We’ll look for opportunities for material consolidation, re-engineering and substitution as well as die size reductions and migration to technology solutions using six clearly defined stages:

Pre-assessment data gathering

Plant-level assessment

Data entry/specification organization, including samples engineering prints and performance requirements

Cost reduction project identification

Formalized cost savings report

Implementation

Can you tell us about your production capabilities?

We pride ourselves on the wide selection of materials, substrates and adhesives we use to ensure your order is produced to your exact specifications. Our state-of-the-art digital, flexo and screen printing capabilities give us the flexibility to deliver cost-effective print runs of any size or complexity.

Our on-demand digital production enables efficient, low-volume runs of highly complex label designs. Your labels won’t become obsolete in a warehouse. They’ll be produced as needed and can be easily updated through simple drawing changes.

We also offer thin and direct thermal linerless labels that help eliminate waste, reduce the number of SKUs and roll changes you need, and lower storage and distribution costs.

Do you have stock labels available?

Absolutely. Taylor has one of the largest selections of stock labels in the industry, offering a wide array of options to meet all your needs. We provide same-day shipping for all stock orders received prior to our shipment cutoff time.

Thermal transfer labels

RFID-enabled labels

Direct thermal labels

Cut-sheet, laser and inkjet labels

Integrated form-label constructions

Impact/EDP/pin-fed labels

What are your methods for keeping us in compliance?

We realize the importance of meeting regulatory requirements in your label designs and finished items. That’s why Taylor collaborates with UL, cUL, CSA and ANSI to ensure compliance based on industry, usage and state standards.

Taylor’s experienced and knowledgeable team can support your individual needs. We require all of our material vendors to update material compliance statements annually to ensure regulatory statuses are current. Additionally, we provide and offer support for REACH, RoHs, conflict minerals and California Proposition 65 for industrial label markets.

Whether you need certified materials, design compliance, a basic compliance statement or a Full Material Disclosure, you can count on Taylor to offer practical solutions to complex challenges.

Can you help us with inventory management?

Certainly. We offer world-class logistical capabilities for label programs of all types. We deliver sophisticated, mobile-ready vendor managed inventory services that eliminate stock-outs, maintain inventory to meet spikes in demand, and reduce the total cost of ownership of each component part.

Data-driven demand forecasts are utilized to minimize on-hand inventories while optimizing least-cost production models. Storage and fulfillment are managed through our nationwide network of in-house distribution centers. Comprehensive billing and reporting options provide clear visibility to costs, inventory levels and usage patterns. The result is a complete VMI solution that makes label program management a source of competitive advantage for your manufacturing operation.

Do you have eco-friendly packaging and labeling options?

Environmental sustainability is no longer a nice-to-have. Your customers expect it. Taylor’s new earth-friendly label stocks give you an opportunity to advance your sustainability goals while also improving operational efficiency and reducing costs.

Our labeling experts engineered two products that enable you to protect the environment and grow your bottom line.

The first is thin-stock labels. Construction is up to 50% thinner, and you’ll use 27% fewer greenhouse gases and create 26% less waste while streamlining your manufacturing operation with fewer roll changes and lower storage and distribution costs.

Next up are our linerless direct thermal labels. These eliminate the end product that is ordinarily thrown away. Liner waste is reduced 100%, rolls are 75% longer and labels can be cut to exactly the right length for every type of label needed, reducing the number of SKUs in use.

Be Authentic and Memorable

Packaging and labeling protects, informs and relates to your customers. Count on Taylor to deliver your brand’s message and values.