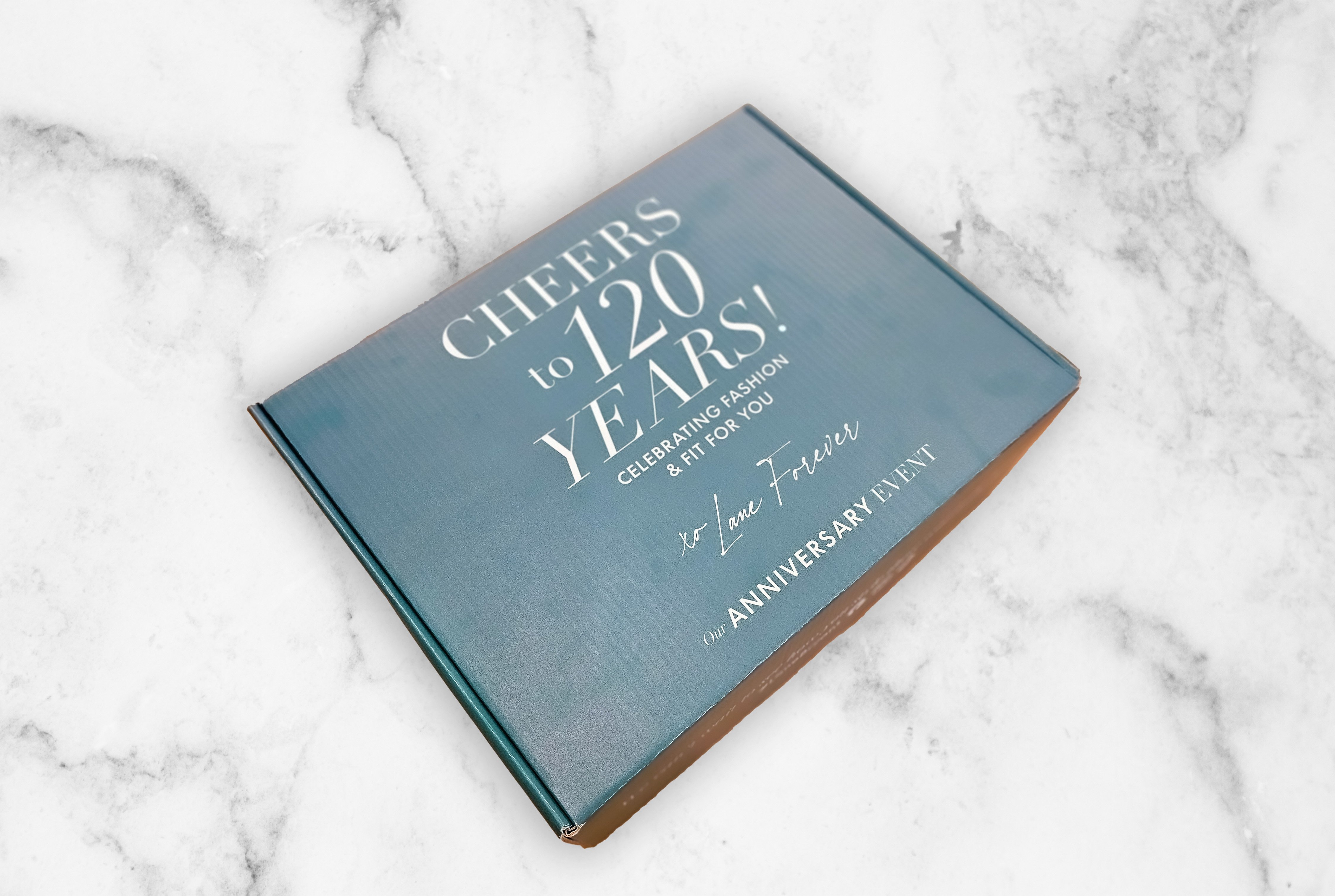

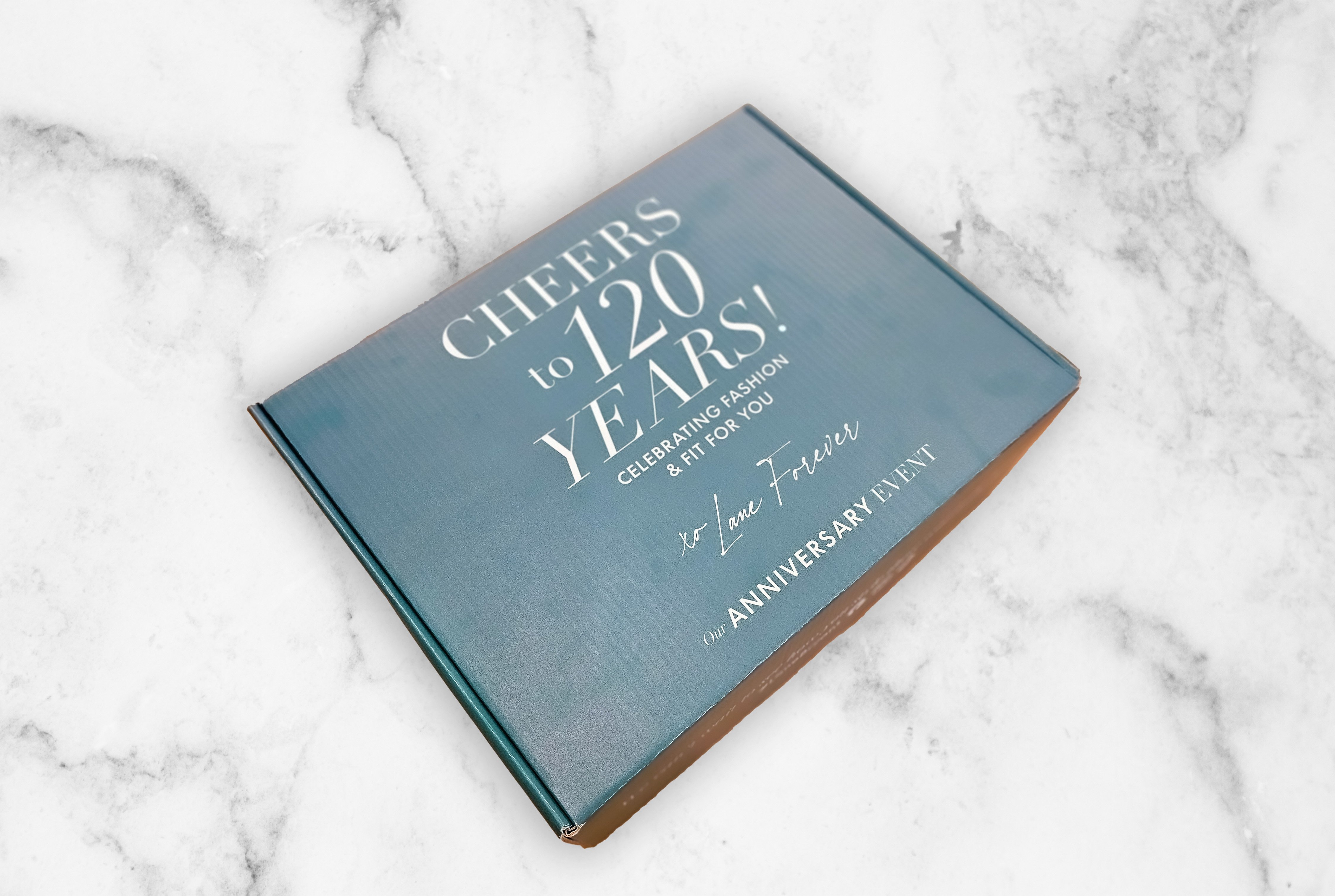

Taylor helped Lane Bryant celebrate 120 years with custom packaging that sparked influencer excitement and unboxing buzz nationwide.

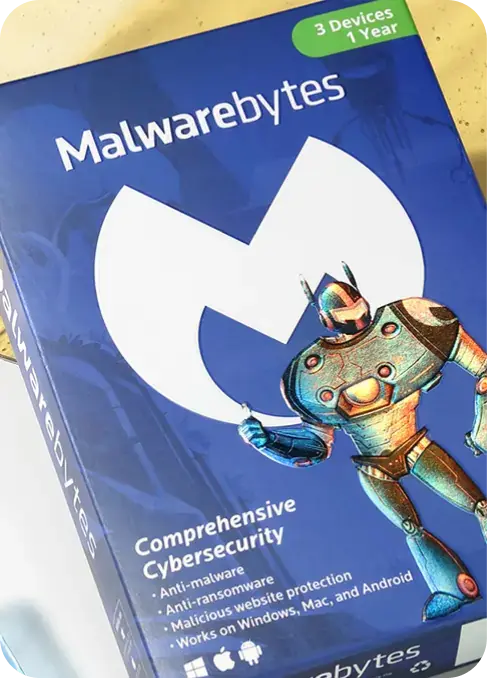

From LPs and gaming releases to CDs, DVDs and Blu-Rays, Taylor has the innovative print and packaging solutions to deliver any type of experience you can envision.

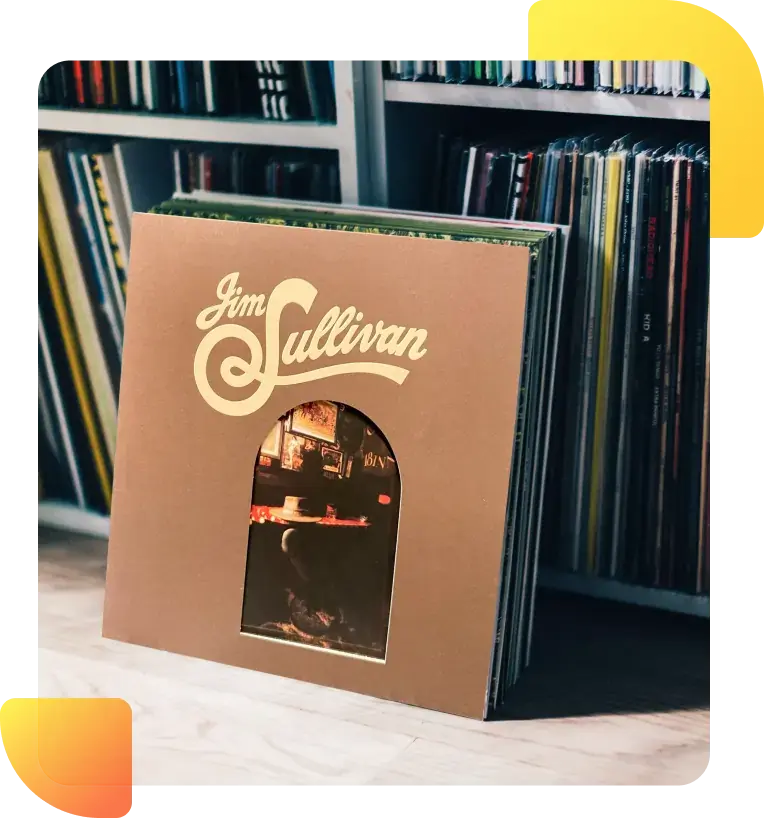

Your single source for vinyl LP packaging.

Media packaging is an artform in itself. It goes beyond protection. It serves as a representation of what’s inside. No matter what your art form or the media you use to share it, Taylor is the full-service manufacturer for any of your custom media packaging needs.

Our expertise lies in crafting custom designs that enhance the visual appeal of

your media packaging and the protection to keep the contents inside safe.

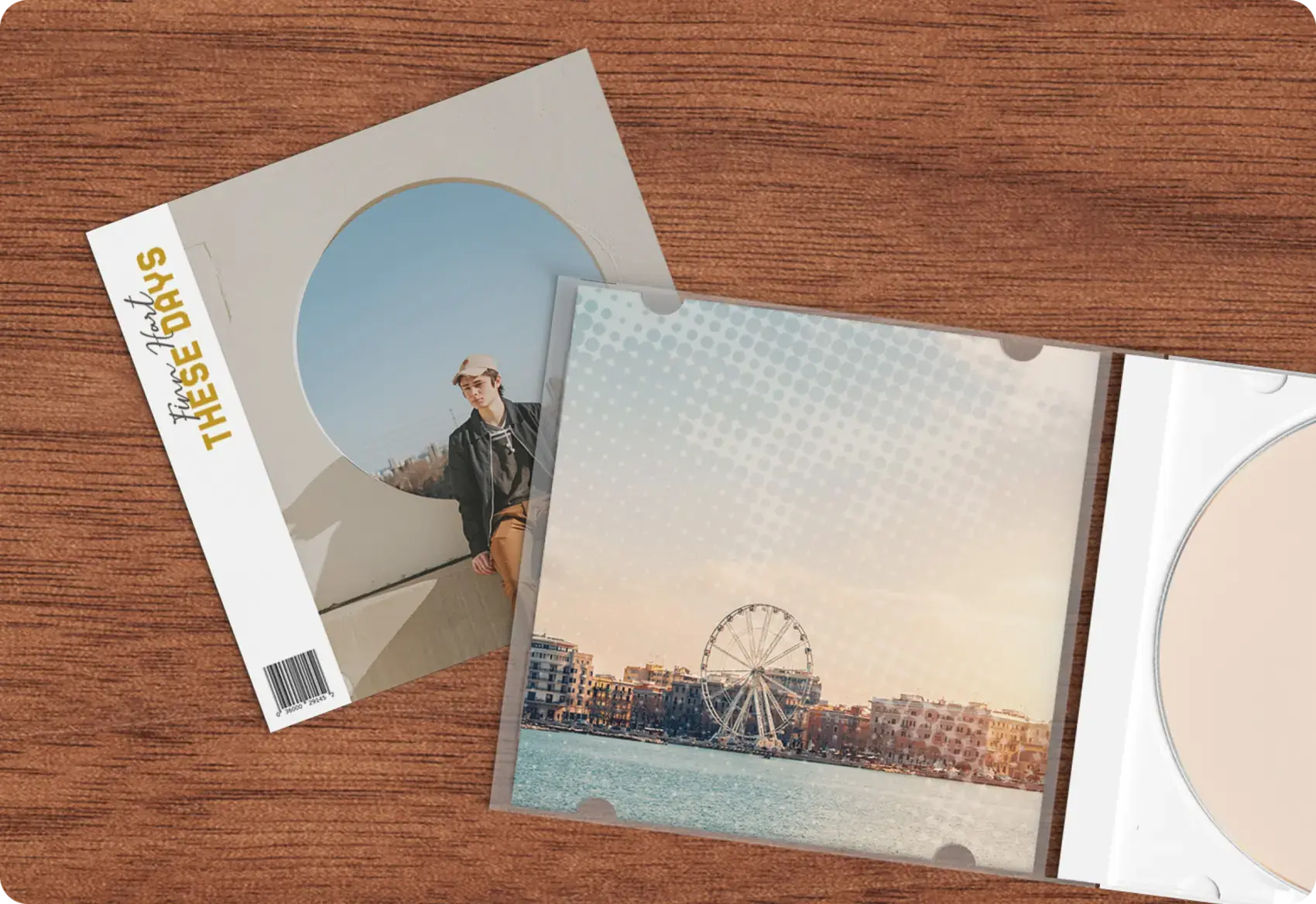

Whether it's the sleek design of a CD sleeve or the nostalgia-inducing feel of a vinyl LP album cover, music packaging sets the tone before even a single note is played. At Taylor, we understand that the right packaging can enhance the fan experience and create a lasting impression.

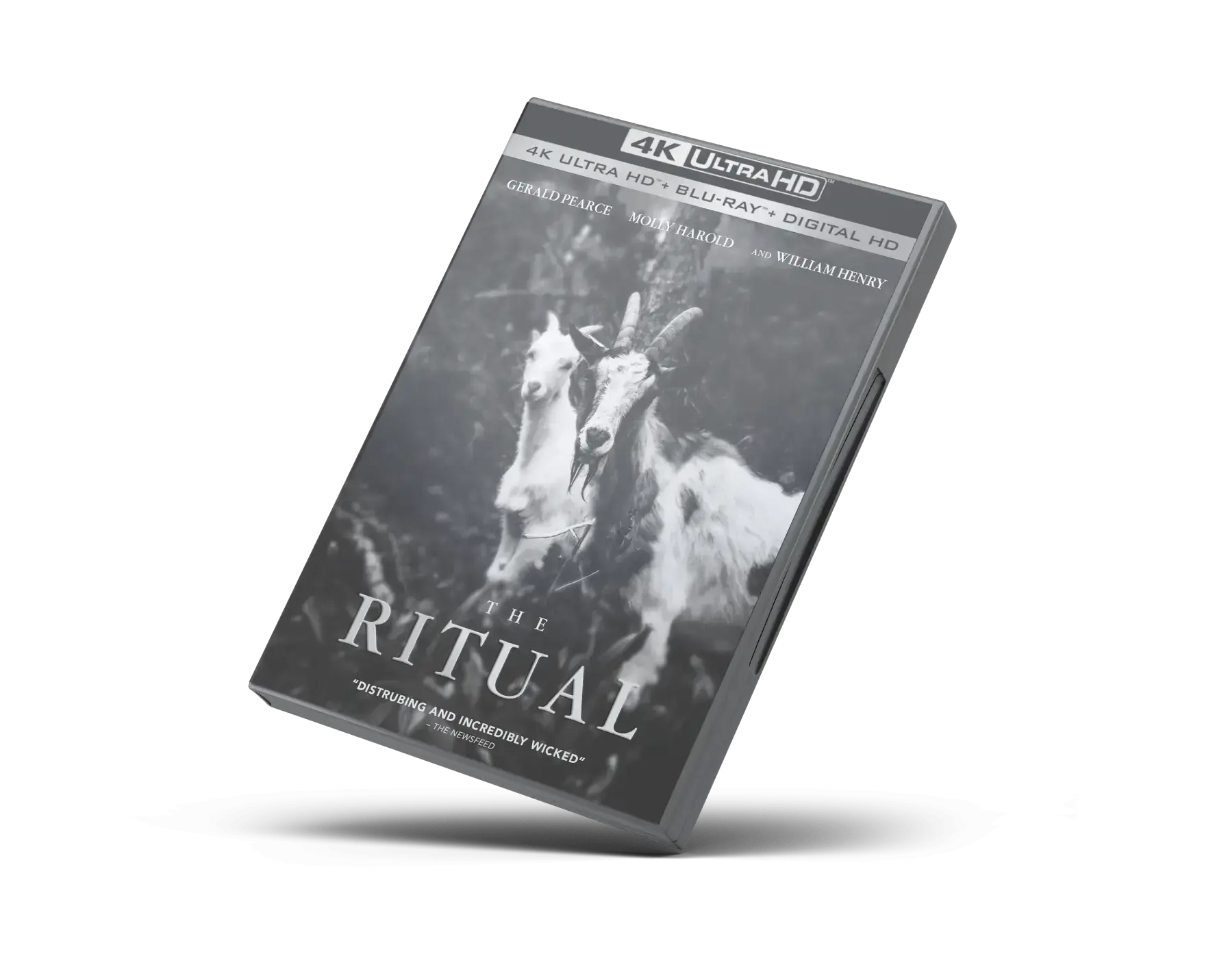

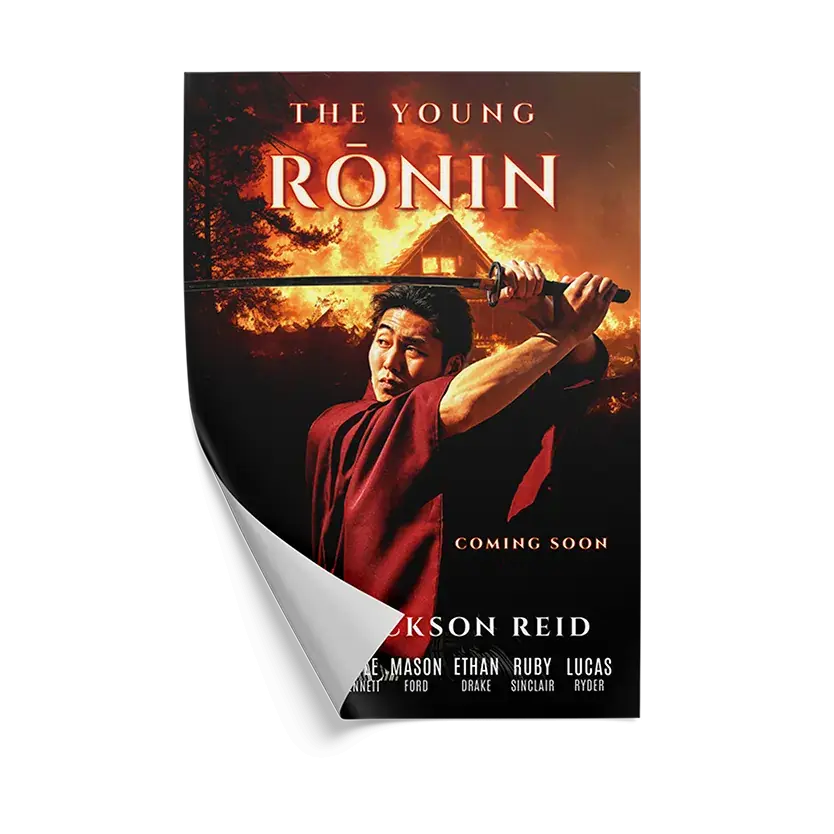

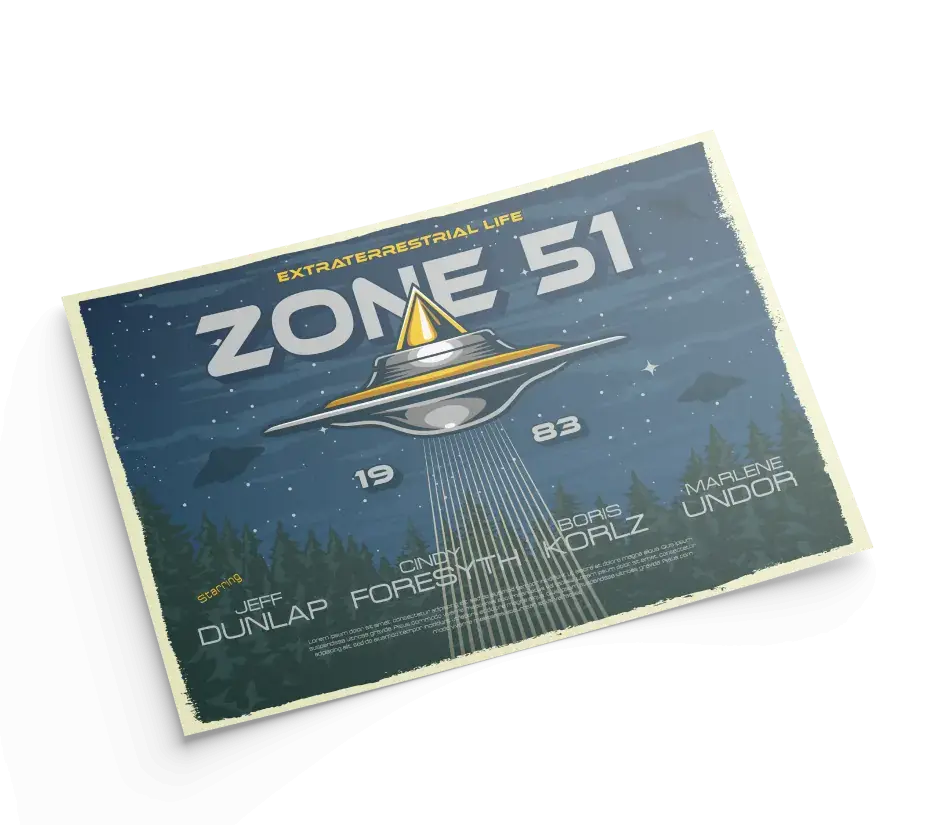

Movie packaging includes visually appealing and protective cover wraps, slip cases and boxes. With Taylor, these not only preserve the DVDs and Blu-Rays, but also capture the essence of the film to make an engaging first impression for the viewer.

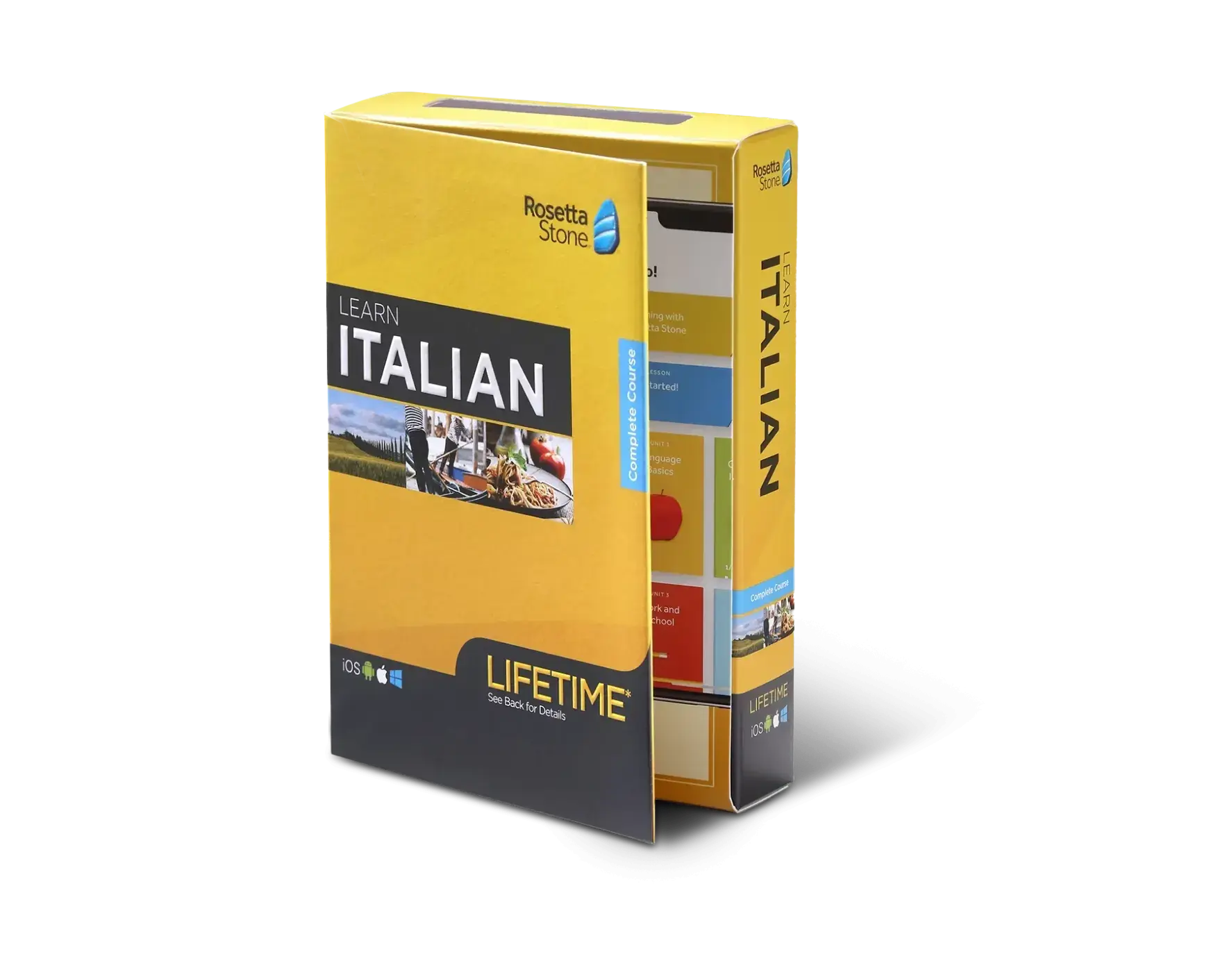

Paperboard is an excellent choice for media packaging because of its versatility, durability and eco-friendliness. In addition to being used for vinyl records, CDs, and DVDs and Blu Rays, paperboard packaging is perfect for video game packaging and software packaging.

Music fans who buy vinyl know LP jackets can be just as important as the

record it holds. Taylor understands the importance of high-quality packaging, not

only to protect the vinyl but also to enhance the overall listening experience.

That’s why we offer a variety of custom LP packaging solutions that create added

layers of interaction and engagement.

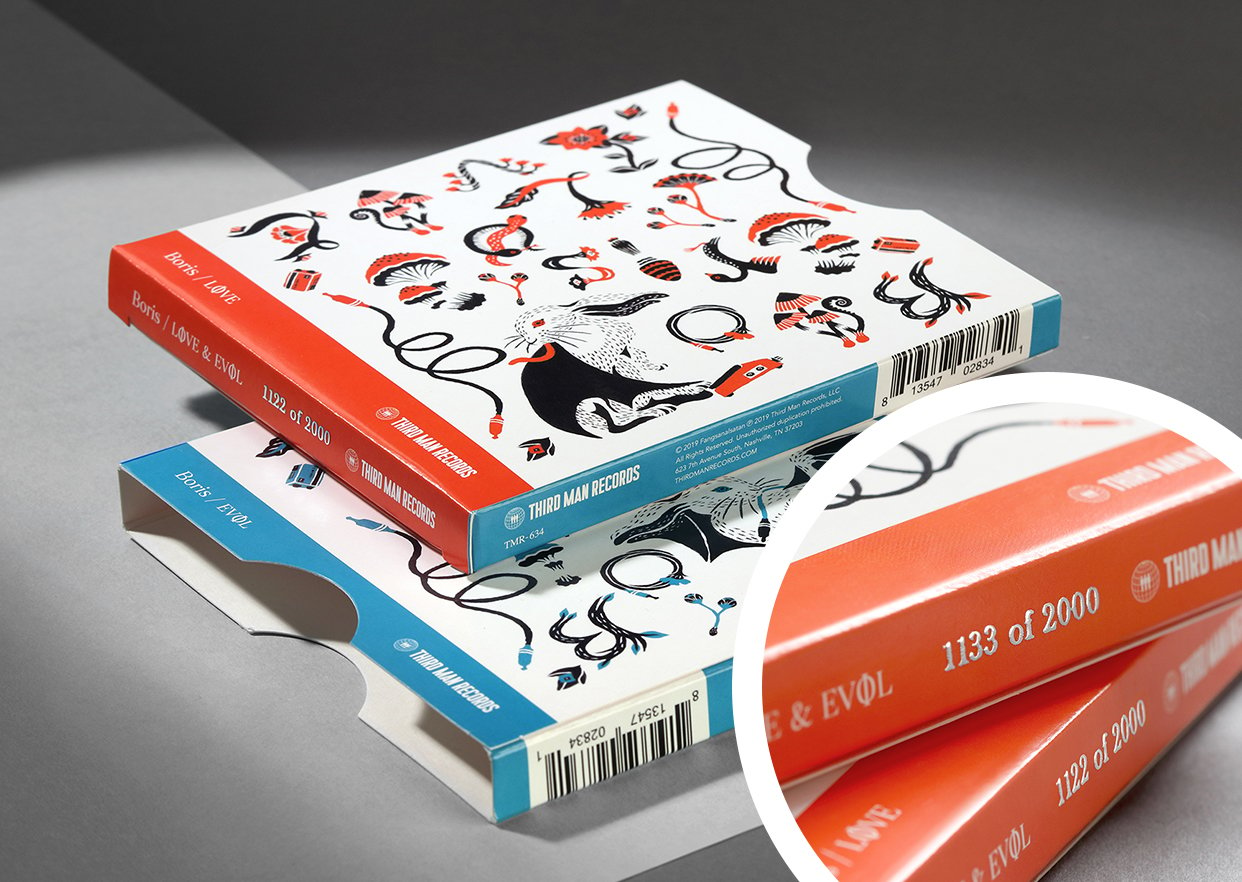

LP album covers can transform a vinyl record into a collectible piece of art. Each component is designed to resonate with the artist's vision, providing music fans with an immersive experience right from the moment they lay eyes on the package.

Vinyl LP inner sleeves serve as the primary covering for records while doubling as a canvas for artistry and branding. These jackets protect the vinyl from physical damage and reflect the musical artist’s style or the album’s theme.

From classic single sleeves with a minimalist look to gatefold jackets that open to reveal additional artwork or lyrics, vinyl LP jackets serve a distinct purpose when it comes to album protection and presentation.

Single jackets are a cost-effective, classic choice for vinyl LP packaging, providing a sleek and straightforward way to present your music while capturing the essence of the album.

Gatefold jackets have a hinged center, allowing them to open like a book. This design provides a larger canvas for artwork, band photos, liner notes and song lyrics.

Wide-spine LP jackets are designed to accommodate multiple records, ideal for albums featuring extended content or bonus tracks that enhance the musical journey.

Trifold jackets have three panels, offering more surface area than traditional jackets, be utilized for creative layouts, incorporating photographs, lyrics, or exclusive artwork

Die-cut jackets add a layer of sophistication, allowing for unique shapes or windows in the design that provide a sneak peek of what's inside.

Vinyl LP box sets offer an elevated and comprehensive packaging solution for housing multiple records alongside additional printed companion pieces like art prints, posters, booklets and more. Box sets showcase the special or rare nature of album releases.

Taylor’s vinyl LP packaging solutions also include an array of additional custom-printed materials that

complement and enhance the listening experience.

Record sleeves are available in a variety of materials including paper, plastic and poly-lined options. They prevent damage to the record and can be used for custom designs and artwork.

Inserts allow artists to include lyrics, exclusive artwork or liner notes, while folders provide a protective and organized space for these inserts.

Center labels can be printed with a variety of finishes and designs that contribute to the look of the record, and serve as a space for legal information, barcodes or special edition markings.

In addition to providing the words to songs, lyric books and booklets can showcase artwork, band photos, insightful notes and more to amplify the experience that comes with a vinyl LP.

Using stickers in vinyl LP packaging can serve many purposes, ranging from branding and logo displays to designs that align with the theme of the album.

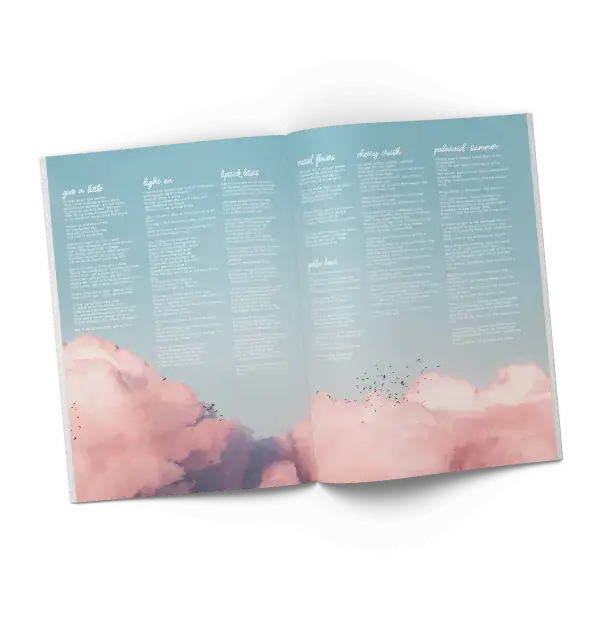

CD packaging plays a crucial part in the presentation and protection of any disc. It must combine convenience and durability with visual appeal. At Taylor, we know that both aspects have to be designed to meet your unique needs.

That’s why we offer a variety of custom CD packaging solutions that provide your products with the protection and artistry they need to stand out on the shelf.

CD tray cards and booklets add to the tangible experience of owning a physical CD. Their artwork and design can make a CD more attractable to potential buyers, and they can offer listeners insights about the artist and the creation and recording of the music inside.

CD sleeves are a single-pocket envelope made of paper or thin cardboard, opening at the top or side to insert the CD. CD sleeve printing gives you a sleek, cost-effective option with enough space for graphics to grab a customer’s attention.

CD wallets are a four-panel cardboard case with a spine and open like a small book. With its sturdier construction, they provide better protection compared to a sleeve and more space for artwork and information.

Digipacks are a popular and versatile option for CD packaging. They consist of a plastic tray attached to recyclable, custom-printed paperboard stock, offering a stylish and protective blend of functionality and impactful visuals.

CD box sets are designed to showcase multiple albums alongside special collectible items, such as booklets filled with rare photos, detailed artist biographies and insightful liner notes. This requires high-quality printing materials and enhancing finishes that elevate the presentation.

For movie fans that buy physical copies of their favorite films, packaging can be one of the deciding buying factors. With years of experience designing solutions for the film market, Taylor knows that packaging should reflect the viewer’s connection to the film.

That’s why we offer a variety of custom DVD and Blu Ray packaging solutions that deliver protective, high-quality packaging that creates connections digital delivery cannot match.

Slipcases are printed sleeves designed to slide over standard DVD and Blu Ray cases. Beyond protecting the case inside, slipcases give distributors an additional surface for creative design and opportunity to add a premium feel to the release.

Limited edition boxes make an edition of the film exclusive and unique. Their design sets them apart from standard packaging and gives the viewer an enhanced unboxing experience, as these limited editions can hold supplemental discs and materials unavailable anywhere else.

In addition to outer box and cover art, movie packaging can include

supplemental printed materials that add to the viewer’s experience and

pride in owning the film.

Inner booklets give viewers further insight into the film they’re watching. These can contain details about the film's production, interviews, essays and exclusive photographs.

Film posters are often included as part of limited edition sets as collector’s items. They add extra allure to the movie’s packaging, and can be saved or displayed by fans.

Lobby cards can be a collectible callback to classic theater experiences. They can also give viewers a glimpse of the art and advertising used at the time of the film’s theatrical release.

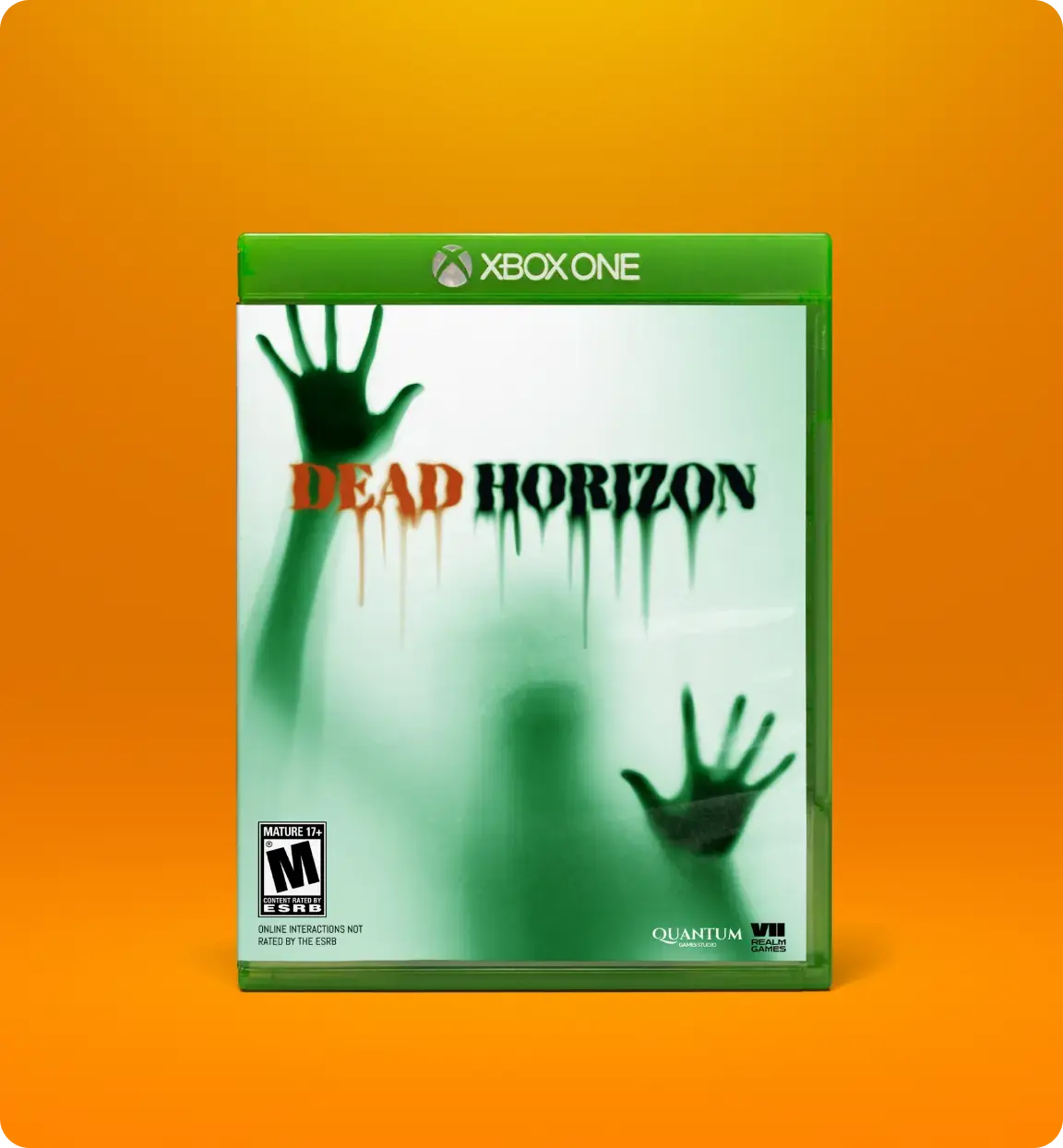

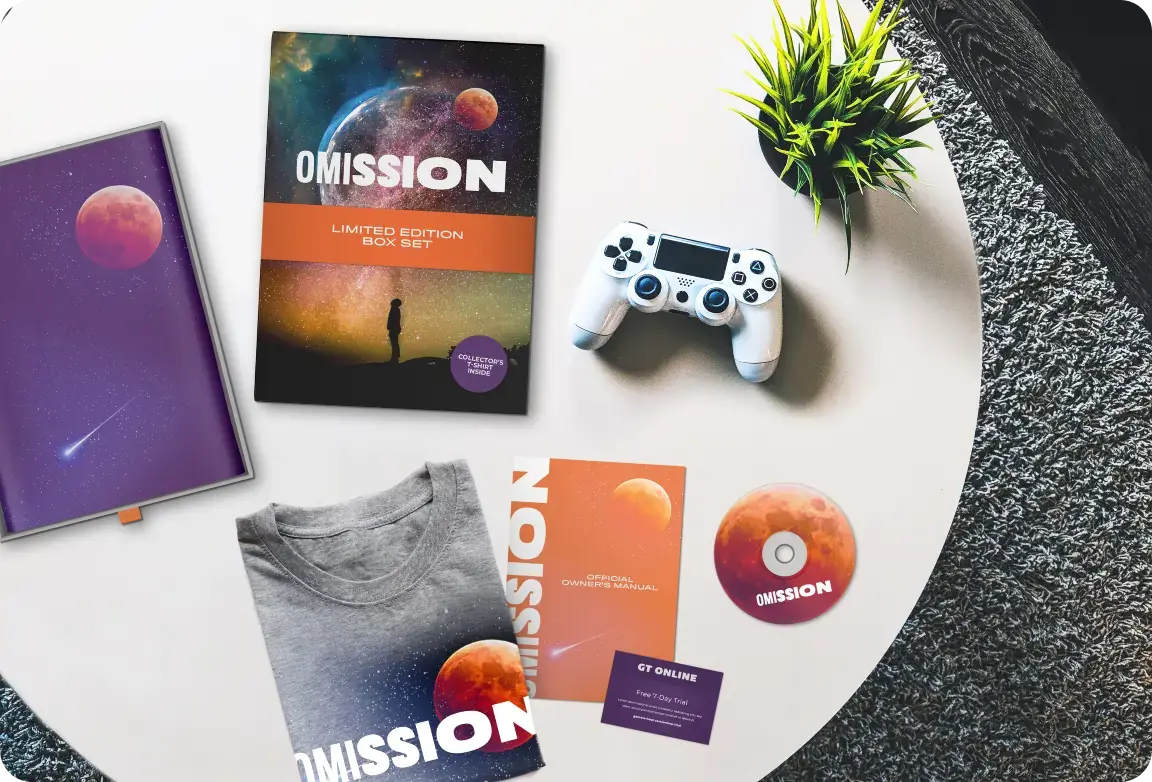

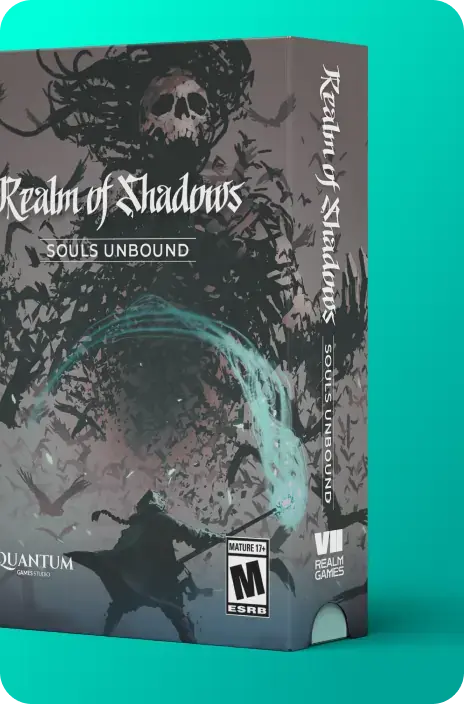

Gaming and software packaging is held to the same standards of the product

inside - with each edition, the stakes have to be raised. Taylor understands

the important role packaging solutions play in meeting the customer’s

expectations before they even start unboxing.

Flexible paperboard and cardboard cartons are versatile solutions for gaming and software packaging. They are great combination of functionality and artistic appeal, and can be tailored to the exact size, shape and other requirements of the products inside.

Wraps are designed to serve various needs across different types of games and software. They work as protective covers and can be used as marketing tools to garner attention.

Inserts are used for essential information such as installation guides, game overviews or software key codes, and are also great for exclusive offers or game expansion details.

Taylor’s gaming and software packaging solutions also offer additional custom-printed

materials that add to the gaming experience, help guide software education and increase

brand loyalty.

Books can play a large part in gaming and software packaging. They include manuals, illustrated guides, story companions, art collections and other publications.

Promotional products increase brand recognition and add value to gaming and software products. They can include T-shirts, posters, stickers, tote bags, keychains and other items.

Taylor’s state-of-the-art facilities are equipped with the latest technology,

ensuring high-quality printing that captures the essence of your creative work.

We understand that every project is unique, and thus, we provide customizable

solutions that cater to specific media forms.

Our in-house CAD department will help you design and test multiple options until we find the perfect media packaging option for your product.

Taylor offers cutting-edge printing and creative techniques to ensure that your media packaging is both visually compelling and aligned with your marketing goals

Taylor’s print and finishing experts create packaging embellishments that make your media stand out from your competition.

Paper cartons and paperboard boxes are biodegradable and renewable by nature. Using these and other eco-friendly materials for your media packaging gives you a significant sustainability advantage compared to plastic packaging.

Taylor provides all the printing, binding and other commercial book printing services you need for the essential supplemental book and booklet inserts you want to include in your media packaging.

With 12 patents for lenticular printing, Taylor gives you access to some of the most sophisticated media packaging printing and finishing techniques available today.

Lenticular printing allows you to create media packaging with images that give the illusion of depth and motion.

Media packaging can feature any lenticular effect you want to help your vinyl record, DVD or Blu Ray, game, and software packaging to attract attention and increase value with customers.

Taylor helped Lane Bryant celebrate 120 years with custom packaging that sparked influencer excitement and unboxing buzz nationwide.

Stick packs and sachet packs are two forms of flexible packaging that are ideal for single-serve, on-the-go use of consumer packaged goods

WineSociety™ needed unique can labels fast. Taylor’s Prime Labels team delivered innovative printing solutions in two weeks, ensuring a successful lau...

Taylor used its folding carton packaging expertise to provide the fast, scalable solution Dole needed to extend distribution.

Shrink sleeves offer increased shelf-appeal, brand protection and versatility compared to pressure-sensitive labels and other forms of packaging.

Packaging formats including flexible pouches, shrink sleeves and pressure-sensitive labels are well-suited to the packaging of pet products.

Spouted pouches are a form of flexible packaging that is ideal for petroleum products like motor oil and other petroleum-based automotive fluids

In addition to QR codes, NFC chips and nanotechnology, RFID smart packaging technology is fueling growth in the labels and packaging industry

Folding carton packaging made from paperboard can be used to build brands for consumer packaged goods

Dairy product labeling and packaging including stand-up pouches and pressure-sensitive labels with QR codes are driving dairy packaging innovation

Digital printing of labels and packaging protects brands and supports anti-counterfeiting and anti-imitation efforts for consumer packaged goods

Dive into the Global Supply Chain Trends of 2024. From paper to packaging and promo marketing, discover the raw materials trends impacting your busine...

The size of the label on a vinyl record depends on the size of the record. On a 12-inch vinyl LP, the standard label size is 100 mm in diameter. If you are producing a picture disc where the surface of the record is covered with an image as opposed to standard black vinyl, the label is 292 mm in diameter.

For 10-inch vinyl, the standard label size is still 100 mm in diameter, but the picture disc label size is 242 mm. If you’re producing a label for a 7-inch vinyl record, the standard size is 84 mm in diameter, with a picture disc label size of 168 mm in diameter.

The standard size for a 12-inch LP record cover is 12.375 inches square. The artwork for an LP cover needs to be ¼ inches to ⅜ inches larger than the cover itself, and should include a 5mm bleed area around the edges.

For 10-inch vinyl records, the image cover size is 10.375 inches by 10.375 inches. This size is primarily used for extended play vinyl records (EPs). If producing a cover for a 7-inch vinyl record, the cover image should be 7.25 inches by 7.25 inches.

Printing LP album covers begins with design preparation. The design for your LP can be created using Adobe Photoshop or Illustrator. The design must be in CMYK color mode and at a 300 DPI resolution.

Next, you will use a template provided by your manufacturer, which will include guides for the front cover, back cover, spine and bleed areas. After you’ve placed your artwork within these template guides, double check to make sure it is properly scaled and positioned.

Verify the color mode and adjust for any differences between RGB and CMYK. Finally, you can save the file as a PDF and send it to your manufacturer for printing.

The standard size for a CD cover is 4.75 inches by 4.75 inches. This square format is designed to fit inside a CD jewel case. Many covers do include a bleed area, which requires an extra ⅛ inch of space beyond the area of the finished size. CD booklets should also adhere to the 4.75 inches squared measurement to fit inside the jewel case alongside the CD cover. Standardizing the sizes of CD covers and booklets makes it easier for the consumer to organize and store CDs.

The design process for a CD cover follows many of the same steps as the LP design process. After choosing a photo editor, such as Adobe Photoshop or Illustrator, you can create your cover within your manufacturer partner’s guidelines. These guidelines often include templates for the front cover, back cover, the case interior and the CD booklet if you are including one.

One difference between designing your LP cover and your CD cover is that with a CD, you’ll get to choose between a standard jewel case or slim jewel case. If you have more artwork and information to include, a standard jewel case would work best, and if you want a sleek and modern look, the slim case is a fantastic option.

Before saving your PDF and sending it to your manufacturer, make sure your design is high quality and full-color for the best results when it goes to the printer.