Our recent blog on shipping labels described direct thermal printer labels — arguably the most common type of thermal labeling technology. To create a direct thermal printed label, a heat-sensitive layer on the label’s surface is exposed to a heated printhead. The heat causes the surface of the label to darken, enabling the desired text or image to appear on the label surface.

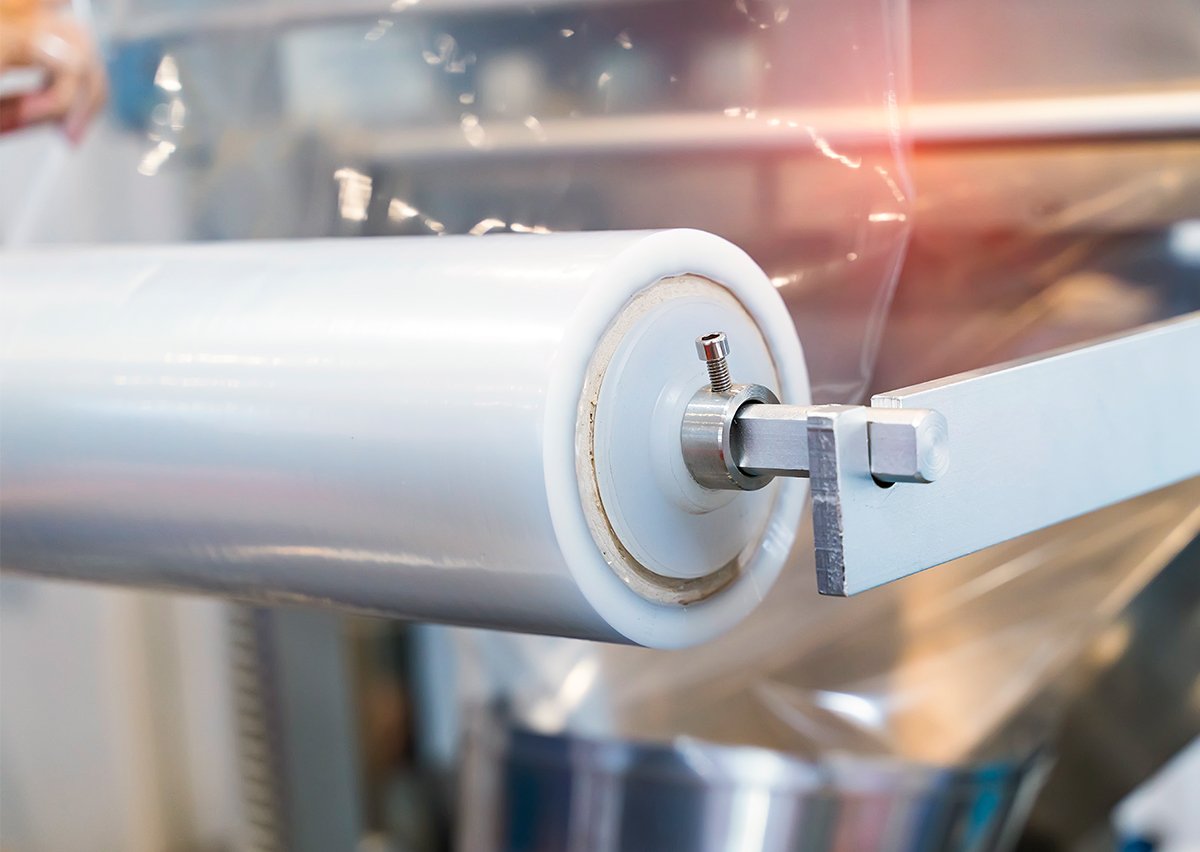

There is, however, another type of thermal label that is created using a very different process. A thermal transfer label printer uses a ribbon coated with wax, resin or a combination of both. The printhead heats the ribbon, transferring the ink onto the label and helping it to bond with the label surface.

The process used to create thermal transfer printed labels results in a label that is more durable than comparable direct thermal printed labels. The added durability opens the door to other types of applications that may not be as well-suited to direct thermal labels.

This blog will touch on the performance characteristics of thermal transfer labels and the types of applications that are ideal for this other form of thermal labeling technology.

The Pros and Cons of Thermal Transfer Printed Labels

When it comes to thermal transfer printed labels, performance is the key attribute to remember.

Thermal Transfer Label Advantages

- Durability: Thermal transfer labels are resistant to abrasion, heat, light and chemicals, making them ideal for use in harsh environments.

- Versatility: Thermal transfer label printers can print on a variety of materials including polyester and polypropylene, offering even more durability advantages.

- Long Useful Life: Unlike certain direct thermal labels, thermal transfer labels can be counted on to maintain readability and scannability over a long period of time.

Thermal Transfer Label Disadvantages

- Complexity: The use of printer ribbons means that thermal transfer label printers are more complex to set up and maintain than direct thermal label printers.

- Cost: The parts and labor involved in changing thermal transfer printer ribbons — and the printer downtime that results — increases long-term operational cost.

- Speed: When compared head to head, direct thermal label printers are typically able to produce labels faster than thermal transfer label printers.

Though durability is always a desirable label attribute, the higher cost, greater complexity and slower printing speed means thermal transfer labels are not as well-suited for mass-volume applications, such as the creation of shipping labels. However, they can be a better choice than direct thermal labels for other types of applications.

Common Uses for Thermal Transfer Labels

- Product Labels: Thermal transfer labels are commonly used in manufacturing for product identification and compliance labels, applications in which durability and long life are vital.

- Asset Tags: Labels created using a thermal transfer printer are ideal for labeling valuable equipment and assets that require long-term tracking.

- Laboratory Labels: Thermal transfer printed labels are generally preferred by laboratory services companies for specimen labeling. Here again, the ability to withstand harsh conditions while maintaining scannability is of paramount importance.

Thermal Transfer Labels from Taylor

Taylor supplies custom-engineered labeling solutions for industrial and consumer packaged goods (CPG) applications of nearly every type. This includes the thermal transfer label printing technology described above. Featuring a high-bond adhesive for durability, Taylor’s thermal transfer labels are designed to ensure printability and error-free scanning. Choose from soft matte, ultra-white facestock as well as gloss polyester, silver and other options.\

Looking for custom packaging and labeling solutions that can enhance the performance of your business? Contact your Taylor representative to learn more.